Auburn acquires next-generation 3D carbon fiber composites printer for hypersonic research

Published: Dec 16, 2025 7:45 PM

By Jeremy Henderson

Auburn University’s Applied Research Institute (AUARI) in Huntsville is adding some serious fiber to its diet.

In collaboration with Auburn University’s Center for Polymers and Advanced Composites (CPAC) and the Department of Aerospace Engineering, the institute recently acquired a CF3D Enterprise Cell — a next-generation 3D carbon fiber composites printer set to define the future of the nation’s hypersonic programs.

Developed by Idaho-based Continuous Composites, the CF3D system represents a highly specialized advanced manufacturing capability and is the only system of its kind currently operating in Alabama.

“This is a first-of-its-kind capability for the region,” said Luke Boyer, lead principal research engineer and head of AUARI’s Design for Additive Manufacturing group. “There are very few CF3D systems in existence, and being the only institution in Alabama with this technology positions Auburn as a hub for large-format continuous-fiber composite manufacturing. It’s going to get the attention of the right people in Huntsville.”

Continuous Composites CEO Steve Starner agrees.

“Huntsville continues to be the gravitational center of hypersonic development in the United States, and Auburn is investing where it matters,” Starner said. “The addition of a CF3D Enterprise Cell gives Auburn and its partners a modern composite manufacturing capability and a toolset to explore structural concepts that were previously out of reach.”

Unlike traditional composite layup processes, the CF3D deposits continuous fiber along optimized load paths, enabling highly tailored strength-to-weight performance.

Boyer said that capability fundamentally changes what engineers can design.

“You’re not just printing material — you’re printing structure. CF3D lets us steer fibers exactly where the loads demand them, and it opens an entirely new design space for our aerospace and defense partners,” he said.

Suhasini Gururaja, associate professor of aerospace engineering, emphasized the transformative potential of the technology for hypersonics materials research.

“For the first time, we can envision printing near-net-shape, architected composites with continuous fibers running through complex three-dimensional geometries,” she said. “That level of precision directly translates to improved performance in hypersonic structures — nose cones, leading edges, control surfaces and thermal-protection components that endure g-loads and frictional heating intense enough to melt metal. It fundamentally changes what aerospace engineers like my group can attempt — transforming designs we used to only dream about into structures we can finally realize.”

In addition to materials research and development collaborations with Auburn University’s Center for Polymers and Advanced Composites and aerospace engineering faculty, AUARI is structuring the CF3D platform around an application-driven partnership model, enabling collaboration with both industry and government customers.

“It’s not going to sit behind glass,” Boyer said. “It’s built to support real programs — rapid prototyping, sustainment solutions, flight-ready demonstrators. We’re designing the pipeline so partners can move from concept to validated structure in days instead of months.”

That sort of speed, Boyer said, is especially valuable for Department of Defense sponsors keen on accelerating experimentation and shortening development cycles.

The CF3D system also integrates into AUARI’s broader advanced manufacturing ecosystem — including polymer additive manufacturing (AM), metal AM, inspection, simulation and post-processing — creating what Boyer calls a “full-stack capability” for end-to-end solution development.

“We’re very excited to collaborate in bringing this capability to the university and are looking forward to tackling important materials design and processing research through this joint effort with AUARI and the Department of Aerospace Engineering,” said Bryan Beckingham, CPAC director and Uthlaut Family Professor of chemical engineering. “It will enable students and faculty on our main campus to contribute toward fundamental materials advancements as well as solutions to real-world applications of these materials.”

Boyer believes those real-world applications are also invaluable for another core component of AUARI’s mission — workforce development.

“Students and professionals trained on CF3D will gain skills that are incredibly rare,” he said. “This is the future of composite design and manufacturing, and we’re giving Alabama the talent to lead it.”

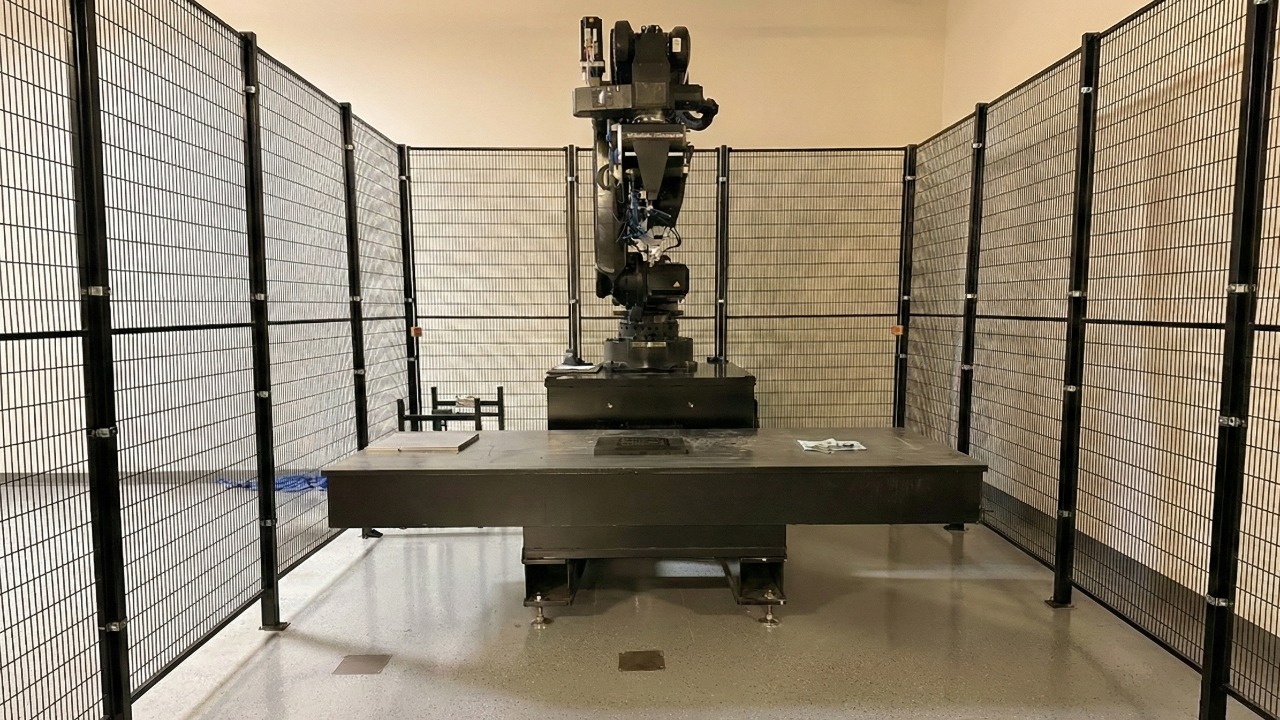

The CF3D Enterprise Cell recently installed at the Auburn University Applied Research Institute in Huntsville. The high-performance, industrial-grade 3D printing system from Continuous Composites is the only one of its kind operating in Alabama.