EPRI director presents on additive in-mold electronics at National Academy of Engineering symposium

Published: Nov 7, 2025 8:00 AM

By Jeremy Henderson

One of the heavyweights of next-generation electronics recently shared his vision for lightweight vehicles with the National Academy of Engineering (NAE).

Pradeep Lall, the MacFarlane Distinguished Professor and Alumni Professor in the Department of Mechanical Engineering and director of Auburn’s Electronics Packaging Research Institute (EPRI), presented at the NAE's Mini-Symposium on Integrated, Flexible, Functional Materials, held Sept. 3. His talk, "Lightweighting through Additive In-Mold Electronics," explored how cutting-edge manufacturing technologies can reduce vehicle weight and improve efficiency.

“A large part of a vehicle’s weight comes from wire harnesses that carry signals between sensors, control units and other systems,” Lall said. “By integrating sensors directly into the vehicle’s touch surfaces using additive printed electronics, we can dramatically cut down on wiring and make systems smarter and lighter.”

Through EPRI, Lall's team is advancing the technology and developing process kits to help automotive manufacturers adopt additive manufacturing (AM) in their electronics platforms. Working with major industry partners like Toyota and John Deere, the team has demonstrated how flexible hybrid electronics can integrate form and function while reducing wiring weight by as much as 75%. Fewer wires means greater fuel efficiency.

“The automotive platform is one of the most challenging environments for electronics,” Lall said. “Reliability is critical, given the long service life and exposure to extreme conditions. Design methods that work fine in consumer electronics often fail in these applications.”

Auburn is working to change that.

The university recently announced its partnership with NextFlex, a national manufacturing institute dedicated to advancing flexible hybrid electronics, and the state of Alabama to establish the new Alabama Node of NextFlex. Led by Lall, a principal investigator or co-PI on numerous NextFlex projects, the statewide hub will accelerate research and industry adoption of advanced packaging harsh-environment electronics.

Lall, an Institute of Electrical and Electronics Engineers Fellow, also leads the development of a Semiconductor Equipment and Materials Institute reliability standard for additive flexible hybrid electronics. In 2023, he was honored with the FlexTech R&D Achievement Award. In 2022, ASME recognized him with the Bar-Cohen Memorial Medal for his pioneering work in designing electronics for harsh environments.

"It was an honor to share our research with the National Academies and highlight how lightweighting and sensor integration can help society by blending aesthetics and functionality in new ways,” Lall said.

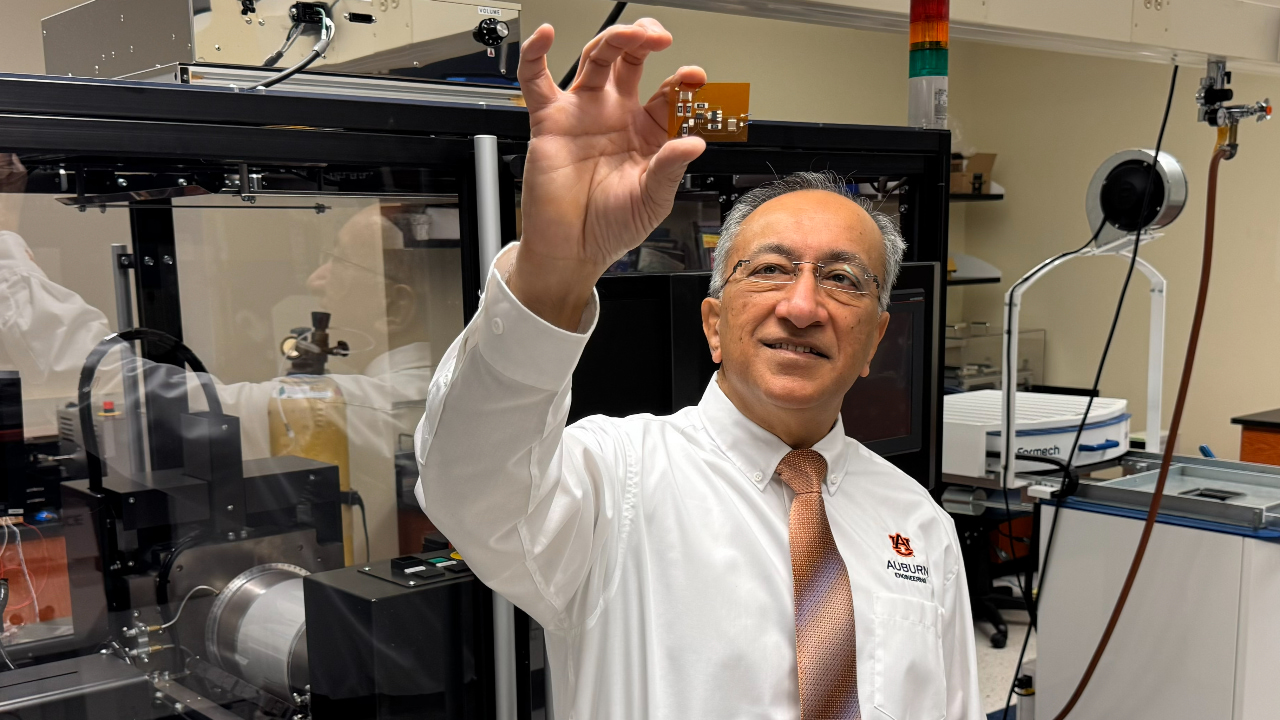

Pradeep Lall, director of the Auburn University Electronics Packaging Research Institute, displays additive electronics for automotive applications.