Auburn Engineering’s additive manufacturing research is key component in NASA’s Invention of the Year

Published: Aug 22, 2024 2:00 PM

By Jeremy Henderson

Auburn's work on the high-tech hardware that will take people to Mars has earned some impressive hardware of its own.

Researchers in Auburn University's National Center for Additive Manufacturing Excellence (NCAME) continue to play a critical role in the Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) project, specifically the project's resulting Thrust Chamber Liner and Fabrication Method technology which, in July, was named NASA's 2024 Invention of the Year.

“This is another in a long list of big achievements for the RAMPT team,” said John Vickers, NASA’s principal technologist for additive manufacturing. “Along with industry partners and with support from NASA’s Game Changing Development Program, Auburn has helped create transformative manufacturing technology that will impact the nation’s space economy.”

NCAME's work on RAMPT, which began in 2019 under a NASA contract now totaling $22 million, involves heat treatment development, materials characterization and structural integrity assessment over a wide range of temperatures aimed at evolving light-weight, large-scale novel additive manufacturing (AM) techniques for the development of regeneratively-cooled thrust chamber assemblies for large-scale liquid rocket engines; few, if any, research labs in the world are better equipped to evaluate the microstructure property relationships in the AM metallic material used for that type of propulsion hardware design.

NCAME's contributions to RAMPT also include the facilitation of a domestic supply chain and specialized manufacturing capabilities available to the government, academic and commercial entities collaborating on the project.

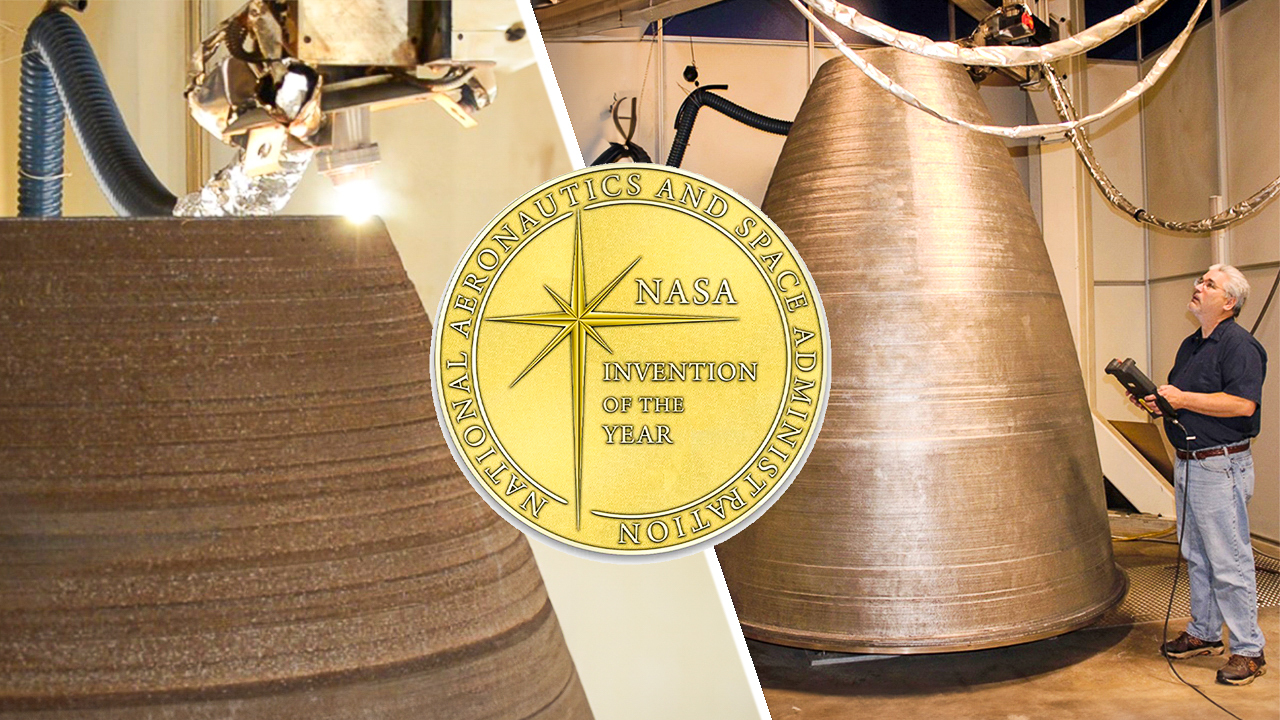

In 2021, the center's expertise factored heavily into the production of a 10-foot tall, 2-ton additively manufactured rocket nozzle liner used by NASA to demonstrate RAMPT's efficacy — likely the largest such component in the world — built in conjunction with leading national metal additive manufacturing firms.

Though the nozzle liner was a significant milestone, NCAME director Nima Shamsaei, principal investigator for Auburn's work on RAMPT, finds the Invention of the Year Award particularly validating — and meaningful.

"NCAME was formed in 2017 through a partnership between Auburn University and NASA, and RAMPT was one of our early marquee projects," Shamsaei said. “That was due largely to the work of Mike Ogles, who was a co-Pi. I know he’d be proud of the award.”

Ogles, a 1989 Auburn mechanical engineering graduate and former director of NASA programs in the Samuel Ginn College of Engineering, passed away in October 2021 after a six-month battle with cancer. Working primarily behind the scenes, his connections with NASA’s Marshall Space Flight Center in Huntsville were instrumental in securing several major research contracts and partnerships for the college — RAMPT chief among them.

Shamsaei also credited co-Pi Steve Taylor, senior vice president for research and economic development, as well as Shuai Shao, NCAME’s associate director for research and innovation, research engineer Tom Hill, program administrator Samantha Allbrook, and Kelley Terry, director of the Samuel Ginn College of Engineering’s office of Research Administration.

“The project’s success is due to the efforts of a great team led by NASA, NCAME, and our private sector AM technology partners,” Taylor said. “Their work went a long way toward establishing Alabama as the go-to state and Auburn as the go-to university for AM research and development. And, obviously, in terms of solidifying NCAME's international reputation as an AM authority, it will pay dividends long into the future.”

This 2-ton, additively manufactured RS25 nozzle liner — the largest component of its kind in the world — was printed in 2021 on the strength of Auburn Engineering research conducted through NASA's RAMPT program.