Aerospace engineering study encourages face mask redesign in the future

Published: Mar 28, 2022 10:00 AM

By Joe McAdory

The COVID-19 pandemic brought about the use of face masks as a means of reducing the airborne transmission of diseases to the center of attention of people around the world. Researchers in aerospace engineering at Auburn University's Samuel Ginn College of Engineering are leading a study that will help improve our understanding of the science that can be expected to guide the design and use of masks in different situations and environments moving forward.

Their research has found that while basic surgical masks offer a first line of defense to both the wearer and the people around them, they are not foolproof as flow leakage occurs around the mask and their effectiveness under realistic coughing conditions is not known.

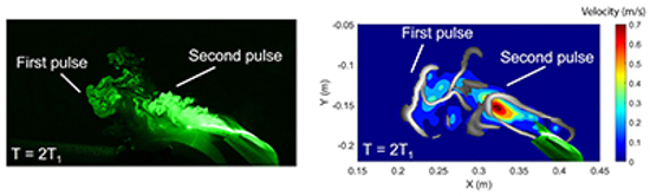

Assistant Professor Vrishank Raghav, Sarah Morris, a postdoctoral research fellow, and William McAtee, a graduate research assistant, found that repetitive ‘pulsatile’ coughs allow expiratory particles to escape through a surgical mask’s sides and above the nose in their co-authored paper, “Influence of expiratory flow pulsatility on the effectiveness of a surgical mask.”

The study – part of a $464,846 National Science Foundation grant in collaboration with the University of Michigan funded in 2021 – was published as an invited article by the Journal of Exposure Science & Environmental Epidemiology, a Nature publication.

“Our research has found that if you are wearing a mask and you cough, the volume of air that leaks is reduced compared to not wearing a mask,” Morris said.

“However, the effect of pulsatility does influence the leakage volume and must be considered when this is modelled.”

Raghav said the source of the problem with basic surgical masks — the blue devices most-commonly sold to and used by the public during the COVID-19 pandemic — is pre-loosening as inhaling, exhaling, double, or even triple coughs provide gaps for germs to become airborne.

“The main reason why surgical masks move, and open gaps, is because the air you are breathing in and out cannot easily travel through the tiny pores of the mask,” said Raghav, a recent NSF CAREER Award recipient. “Instead, it slowly pushes the mask out of the way and when you cough, air finds the path of least resistance out of the mask, which is outside the cheeks and above the nose.”

Raghav agreed that masks of higher quality than basic surgical masks can, if worn correctly, provide better protection. “Surgical masks allow significantly more protection than wearing no mask at all, cutting out roughly 85 percent of the expiratory flow,” he said. “Of course, N95s fit tighter, are secure and allow only a fraction of expired air to leak. Further innovations will be required before surgical masks are as effective as N95s.”

Raghav, Morris and McAtee utilized laser imaging, high-speed photography and a coughing simulator to determine surgical mask leakage. This wasn’t any coughing simulator. It was a custom-built mannequin named Gloria – decked out in a blue surgical mask – designed within Auburn’s Applied Fluids Research Group laboratory.

Using the device, a computer-controlled solenoid valve provides desired air flow rates by controlling a pressurized air source at the wall. From there, a pipe ‘throat’ inserted through the mannequin allows air flow from the wall to a one-inch diameter mouth, which is met by the surgical mask.

“We have a computerized control valve that opens and closes to let the air in and out. We control the pulsatility of the air,” Morris said. “We can create a single pulse, a double pulse, or a triple pulse.”

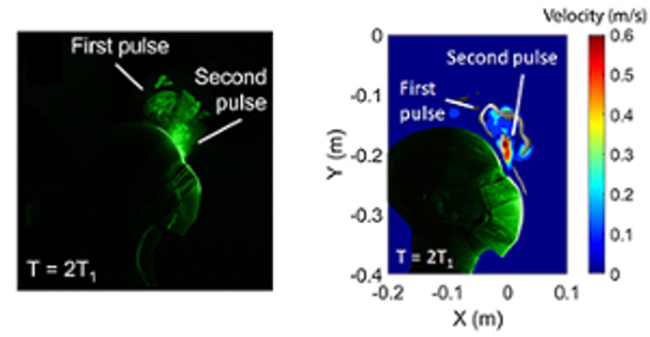

Two main techniques are used to make leakage measurements – flow visualization and particle image velocimetry. With flow visualization – the long pipe carries smoke with two-micron fog particles. When the mannequin coughs, smoke will follow the flow field. A Nikon mirrorless camera is used to capture the expiratory flow — leakage made visible by smoke.

Particle image velocimetry is where laser imaging comes into play.

“This is a quantitative measurement technique where we have these tiny, two-micron particles (representing leaked air) that follow the flow, and we are taking high-speed photos of them,” Morris said. “If we take images at pre-determined times apart, we can actually see where those particles are moving between image one and image two.”

A pulsed, high-speed laser combined with a laser arm and light sheet generating optics illuminates the 2D field of view, providing revealing imagery.

Though mask mandates have currently evaporated in many locations, Raghav pointed out that masks can continue to be useful in many settings.

Media Contact: , jem0040@auburn.edu, 334.844.3447

Researchers, from left, William McAtee, assistant professor Vrishank Raghav, and Sarah Morris, used 'Gloria', a mannequin created by the Applied Fluids Research Group, to serve as a pulsatile coughing simulator.