Additive manufacturing partnership positions Centers for Polymers and Advanced Composites to aid aerospace

Published: Aug 6, 2020 3:00 PM

By Jeremy Henderson

Could additive manufacturing (AM) help the aerospace industry better meet its increasingly strict materials safety standards? Renato Gross is sure of it.

"There is a huge need in the aerospace industry for additive manufacturing, mainly with requirements for nonflammable materials that meet UL 94 plastics flammability standards, and not many solutions are available yet," said Gross, president of Auburn-based additive manufacturing solutions company SWIGRO. "That's one reason why we have great interest in partnering with Auburn."

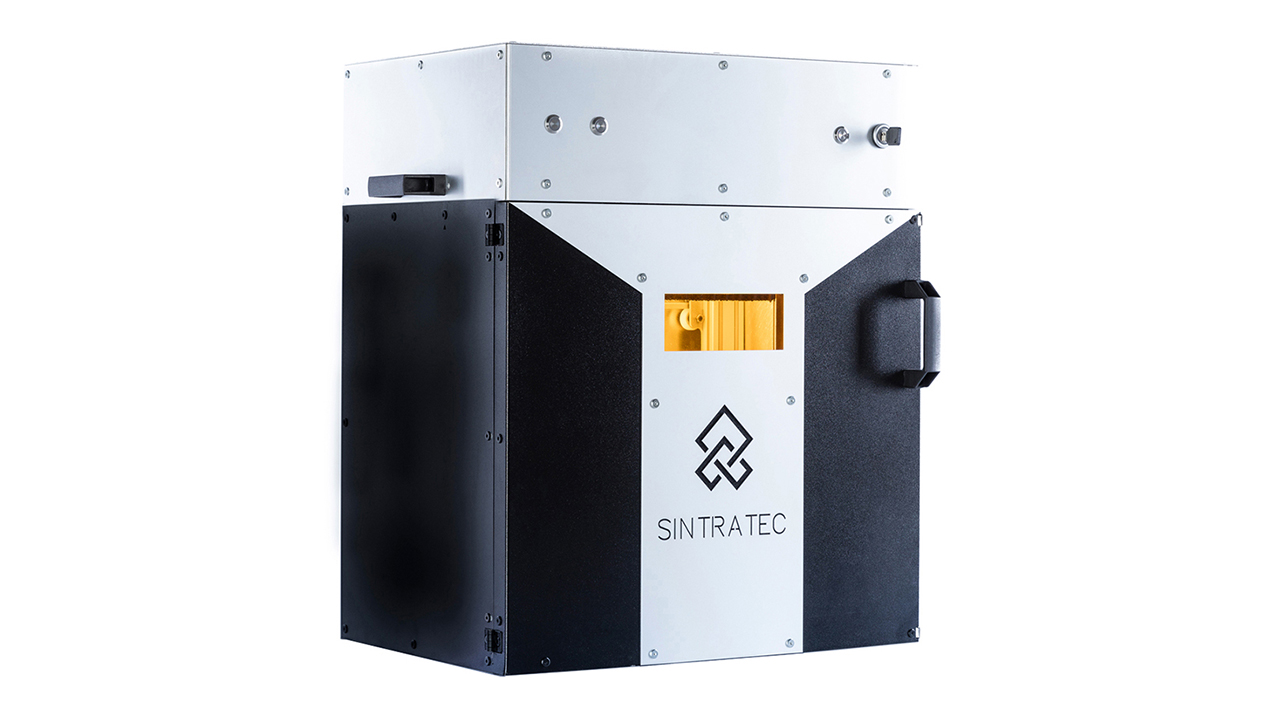

Sintratec and SWIGRO recently gifted a Sintratec KIT, an SLS 3D printer, to Auburn University's Center for Polymers and Advanced Composites (CPAC) to, in part, hasten aerospace industry adoption of AM technology.

Established in 2015, and housed in the newly renovated Gavin Engineering Research Laboratory alongside the National Center for Additive Manufacturing Excellence, the center offers broad expertise in development, manufacturing and testing of polymers and composites.

“The creation and transfer of knowledge for the good of society is an underlying goal of our center,” said CPAC director Maria Auad, W. Allen and Martha Reed Professor and associate dean for Graduate Studies and Faculty Development. “CPAC is dedicated to support and engage with companies like SWIGRO to maximize opportunities for development and collaborations.”

Auad says CPAC faculty focus on development of multifunctional material and composites for structural componentry for performance, added-value and lightweighting.

"There are also opportunities in composites combined with additives manufacturing as the aerospace industry continues to transition from metal to composites," Gross said. "The Sintratec KIT is a great research and development machine that allows for testing of new materials and combinations with laser sintering."

That's what has chemical engineering assistant professor and CPAC faculty member Bryan Beckingham excited.

“I’m really excited about this expanded capability in soft matter 3D printing using selective laser sintering that the Sintratec printer brings to CPAC," Beckingham said. "For our lab, we’ll be extending our research on new functional materials with the ability to self-heal after a damage event to this manufacturing platform. We’re really excited about this and the potential for other future collaborative opportunities with SWIGRO as we work towards improving polymer composites and polymer composite manufacturing.”

Assistant professor Russell Mailen feels the same.

“My research group is extremely appreciative of SWIGRO’s and Sintratec's generosity, and we look forward to continuing our collaborative relationship,” Mailen said. “We are excited to explore the possibilities of precision fabricated structures and high-resolution features that can be attained with selective laser sintering. We will use the new capabilities in our efforts to understand the mechanical behavior of structures fabricated using additive manufacturing.”

Media Contact: , jdh0123@auburn.edu, 334-844-3591

SWIGRO recently gifted a Sintratec KIT, an SLS 3D printer, to Auburn University's Center for Polymers and Advanced Composites (CPAC)