Icams awarded $8.9M for smart manufacturing initiatives

Industrial and Systems Engineering

By Jeremy Henderson

The adoption of Smart Manufacturing is fast becoming a necessity for small and medium-sized manufacturers (SMMs) looking to stay competitive in the Industry 4.0 age. For those SMMs in the national security ecosystem, it’s no longer a suggestion — it’s a requirement. Enter, once again, the Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) at Auburn University.

Established in 2020 to help SMMs bridge the digital divide that threatens to render 85% of the American industrial base obsolete over the next decade, the center will use a significant portion of its latest and largest award from the Department of Defense’s (DoD) Office of Industrial Policy’s Industrial Base Analysis and Sustainment (IBAS) Program, $8.9 million, to leverage its research and outreach efforts promoting advanced manufacturing in small and medium manufacturing operations

“We have to provide SMMs a better understanding of the processes behind new guidelines and best practices necessary to engage in secure work for the DOD,” said principle investigator (PI) Greg Purdy, assistant professor in the Department of Industrial and Systems Engineering. “With this grant, we can equip them with the tools necessary to produce parts in a classified manufacturing environment.”

Whereas, a decade ago, cyber threats were generally exclusive to information and technology (IT) systems, Purdy says that the operational infrastructure of manufacturers is now being directly targeted by malicious actors.

“These days, SMMs can no longer rely on just basic cybersecurity,” Purdy says. “They need to meet even more stringent requirements to protect sensitive information. But some of these smaller organizations and companies, those with under 50 employees, may not think they’re able to offer that level of protection — they may not currently have the resources to.”

Co-PI Gregory Harris, ICAMS director and chair of the Department of Industrial and Systems Engineering, agrees.

“Data integration and analysis in a classified manufacturing environment (CME) is daunting to most SMMs,” Harris said of the issue. “Many are choosing to forego the increased productivity and improved quality available through the application of digital manufacturing technologies because they are worried about the potential for data to escape. During conversations with SMMs, the topic of classified advanced manufacturing continues to be a subject and source of consternation for the nation’s defense industrial base.”

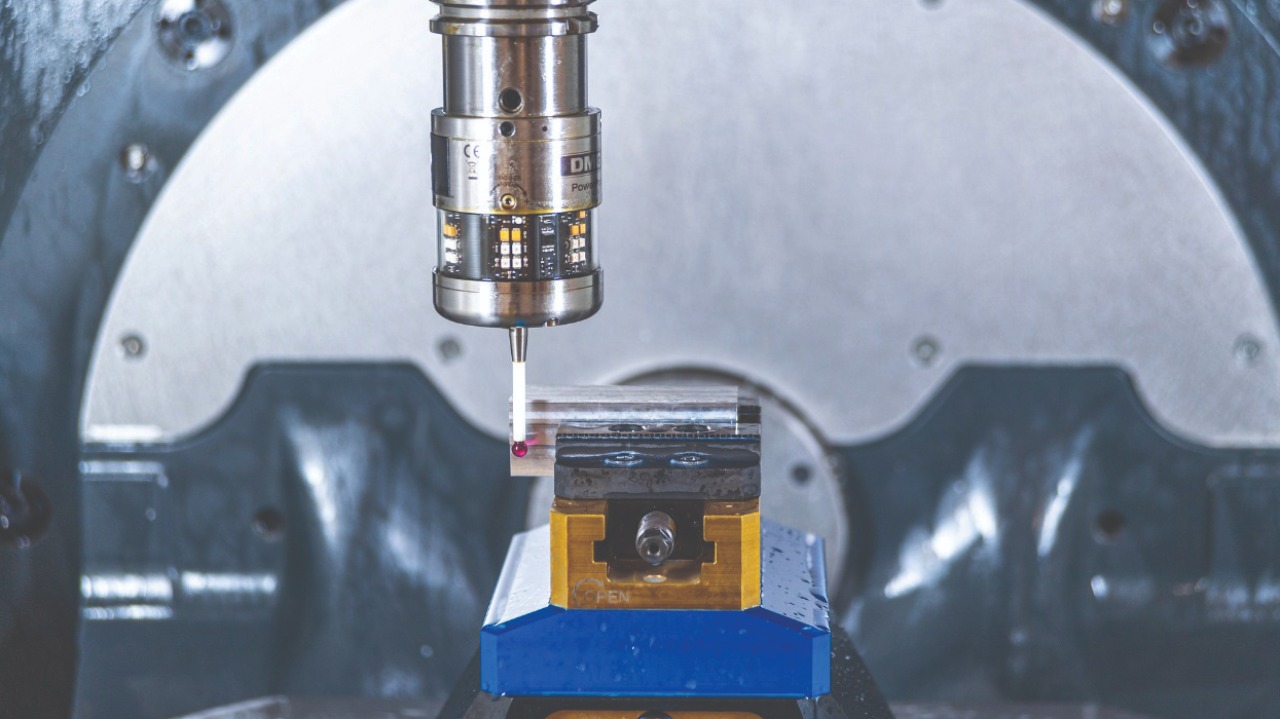

To combat these reservations, ICAMS is creating a CME within its 20,000 square-foot state-of-the-art facility. Located on Pumphrey Avenue in Auburn, the ICAMS production environment already houses waterjet, laser cutting capabilities and welding infrastructure. The ICAMS facility also features dedicated resources in some of the fastest-growing manufacturing sectors, including a 4-axis friction stir welder and a Swiss-style machining center, allowing the center to support a wide range of manufacturing organizations. A Digital Manufacturing Demonstration Cell and Cyber-physical Machining Range is also underway.

However, Harris says that even with the barriers of entry to Industry 4.0 lowered, many SMMs may still find defense manufacturing contracts both a blessing and a curse.

“When demand for a defense part is high, many SMMs add capacity to meet the demand, but then the surge ends, and part orders decrease, even to zero,” Harris said. “Now the SMM has a problem with excess capacity and costs. This feast or famine cycle has been the cause of many SMMs going out of business. The question ICAMS aims to answer is how to address this challenge by developing strategies that allow SMMs to manage the production of parts for the DoD while still maintaining capabilities to produce for commercial markets. Traditionally, this requires duplicating machines and other resources to enable an organization to produce for both markets. However, this tends to disproportionately impact SMMs that may not have the financial capital to duplicate their manufacturing systems. Having unutilized equipment directly affects their ability to stay in business.”

To address this particular challenge, ICAMS will also use the DoD award to develop a Hybrid-Secure Manufacturing (HSM) cell to showcase a flexible manufacturing environment that can produce parts supporting DoD contracts and be quickly reconfigured to produce parts on general commercial contracts.

“This will highlight the security considerations and necessary architecture to allow SMMs flexible DoD and commercial manufacturing at SMMs,” Harris said. “But it will also be valuable in workforce development. We’ll be able to train organizations from the shop floor to the c-suite level. It’s an approach that can help manufacturers understand the business case for HSM through firsthand experience.”

Other tasks the award will help accomplish include ICAMS’ SMM Prototyping Assistance Program, and a technology adoption seed program offering SMMs willing to implement smart manufacturing up to $50,000 in matching funds, an approach that has proven highly successful in South Korean industrial digitization initiatives.

Other co-PIs include Lewis Payton, Peter Liu, Konstantinos Mykoniatis, Yadrianna Acosta-Sojo, Mark Schall, Daniel Silva Izquierdo and Erin Garcia, all faculty in the Department of Industrial and Systems Engineering.