The need for speed: DARPA awards NCAME up to $2.8M for transformative AM qualification research

Published: Sep 5, 2025 11:00 AM

By Jeremy Henderson

The Defense Advanced Research Projects Agency (DARPA) has asked Auburn University to put the pedal to the powdered metal.

The agency recently awarded Auburn's National Center of Additive Manufacturing Excellence (NCAME) up to $2.8 million over four years to support its Structures Uniquely Resolved to Guarantee Endurance (SURGE) program, which aims to significantly expedite and economize how additively manufactured (AM) metal parts are qualified for use.

Currently, tuning a specific machine for qualification, i.e. to repeatedly and consistently churn out the same part with known properties takes a lot of time and costs a lot of money. Multiple years. Multiple millions.

But if researchers could instead predict the life of each individual part at the point of production, using data captured during the actual manufacturing? If critical parts could be printed on any machine, anywhere, at any time, with guaranteed performance?

Well, that's the point-of-need future the Department of Defense envisions as the way to expand the nation's defense industrial base during surge demand.

Enter NCAME.

“We are supporting this DARPA initiative with NCAME’s advanced non-destructive evaluation capabilities,” said Shuai Shao, NCAME associate director for research and innovation and McWane Associate Professor of mechanical engineering. “These methods allow us to detect and characterize volumetric defects in AM metallic parts with unparalleled precision, offering the knowledge needed to establish their process-structure-property-performance relationship with the help of in-situ monitoring and simulation.”

NCAME Director Nima Shamsaei, Philpott-WestPoint Stevens Distinguished Professor of mechanical engineering, additionally emphasized the center’s nationally renowned expertise in validating how defects impact performance.

“NCAME brings deep expertise in the structural integrity of additively manufactured metallic materials, particularly in fatigue and fracture behavior,” Shamsaei said. “Our role is to rigorously validate how microstructural features and defects translate into performance, ensuring that predictive models align with the durability requirements of critical components.”

Stefano Beretta, visiting professor of mechanical engineering and internationally recognized structural integrity scholar, highlighted NCAME’s role in developing probabilistic models.

“NCAME is advancing a probabilistic framework for component life estimation that captures the inherent variability in additive manufacturing,” Beretta said. “By quantifying uncertainty in defect distributions, microstructure, and loading conditions, we are developing predictive tools that move beyond deterministic limits.”

Shao, Shamsaei and Beretta are all co-PIs on the project.

NCAME’s contributions to SURGE will be integrated into research led by the University of Michigan with the goal of shifting industry from slow, machine-focused qualification methods to a flexible, data-driven process that certifies parts in real time. Other team members include University of Michigan-Dearborn; Texas A&M University; University of California, San Diego; Addiguru, a firm providing AM in-situ monitoring and issue detection technology; engineering software providers AlphaStar; and ASTM International.

“Distributed, on-demand production has always been the promise of additive manufacturing,” Shamsaei said. “Through SURGE, we’re helping to make that promise a practical reality.”

Media Contact: , jdh0123@auburn.edu, 334-844-3591

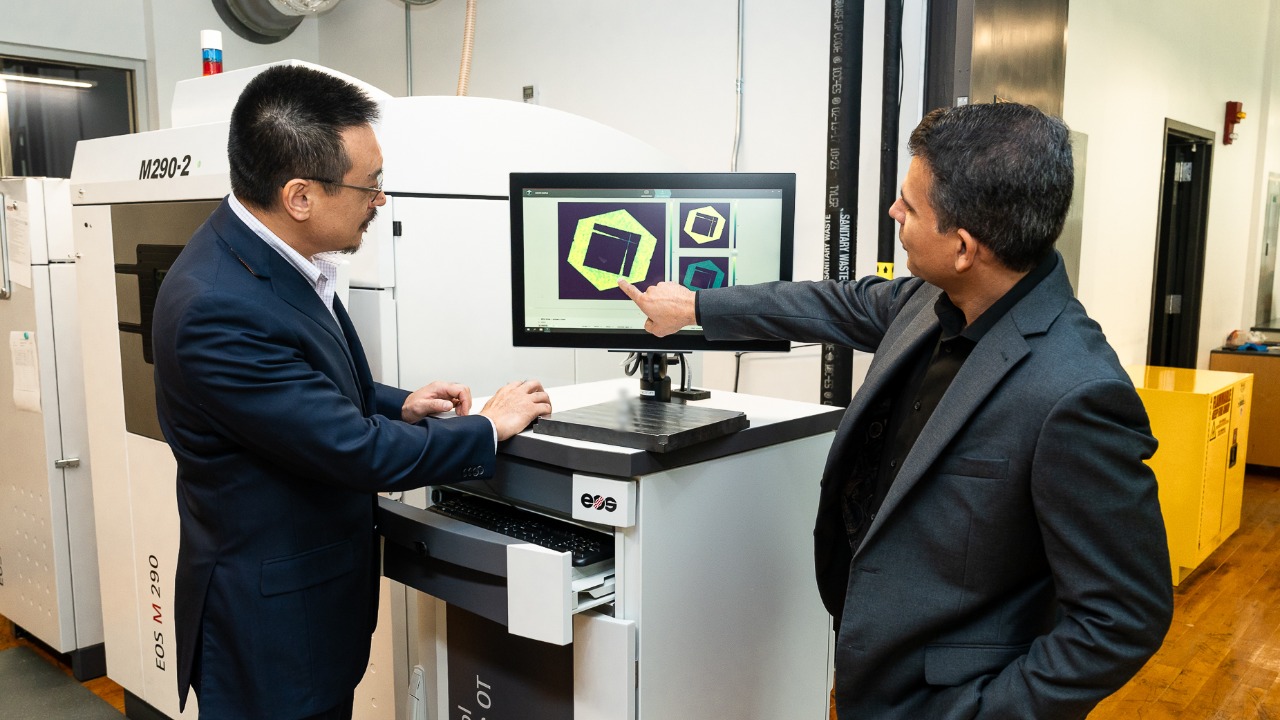

Shuai Shao (left) and Nima Shamsaei review in-situ monitoring data collected from the laser powder-bed fusion fabrication of metallic parts.