A One-Piece Lunar Regolith-Bag Garage Prototype

Excerpt from Final Report

Gweneth A. Smithers, Mary K.

NASA/Marshall Space Flight Center,

J. Scott Miller

Qualis

Corporation/Marshall Space Flight Center,

Roy M. Broughton, Jr., David Beale, and Fatma Kilinc-Balci

3.3 Full-Scale Prototype, and Erecting at MSFC

The full-scale prototype

arch was sewn at Kappler Inc. in Guntersville , AL Mt. Holly , NC

- 20 pockets at the

bottom measuring 6” x 2’ in cross-section.

- 20 pockets above the bottom pockets, measuring 6”

by 1.5’ in cross-section.

- 20 pockets that form the crest of the arch, measuring

6” by 1’ in cross-section.

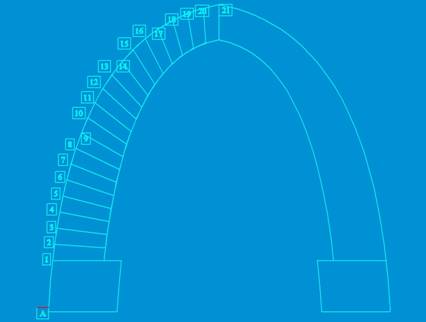

Before discussing the

actual erecting at MSFC using 46 bags, prototype arch designs of a 60 bag catenary shape (e.g. Figure 3.18) were analyzed using the

funicular polygon technique. Under its own weight, the arch of Figure 3.18

revealed that it could hinge (Figure 3.19).

However, taller configurations were found to be stable (Figure 3.20),

and are expected to be able to support more weight.

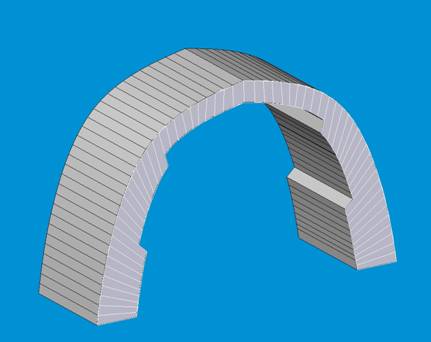

Figure 3.17. Concept Drawing of Arch

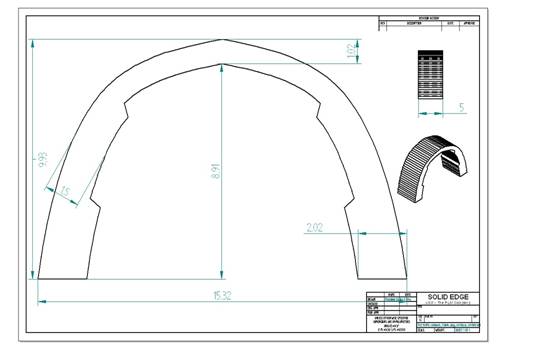

Figure 3.18. Front Dimensioned View, Dimensions in Feet.

Stability analysis using the funicular polygon (Figure

3.19) shows that the structure of Figure 3.18 can possibly form hinges. The

analysis was done assuming no applied forces were acting on the system except

vermiculite weight. One location was identified as lying between the 15th

and 16th bag starting from the left on the figure. Considering that

this structure is symmetrical, the analysis indicates that hinges will form on

the other side as well. Figure 3.19 below shows that hinges appear to form

around the 15th and the 16th bag.

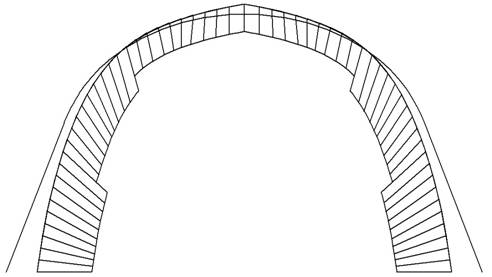

Figure 3.19. Funicular Polygon Showing Possible Hinging in Arch Design

As can be seen in the image above, the hinges will

tend to open towards the outside of the bags, but since these bags are

top-connected by a stiff fabric layer, the fabric layer will prevent any

opening and therefore not allow a hinge to form. Hence this shows that this

configuration may be made stable using the top-connected bag construction. Another

analysis for a wider base below indicates that hinges can form near the 20th

and 21st bag. This formation of hinges is shown in the Figure 3.20.

These hinges will open on the inside of the bags, where there is not a

connecting fabric layer.

Figure 3.20. Another Set of Possible Hinge Locations

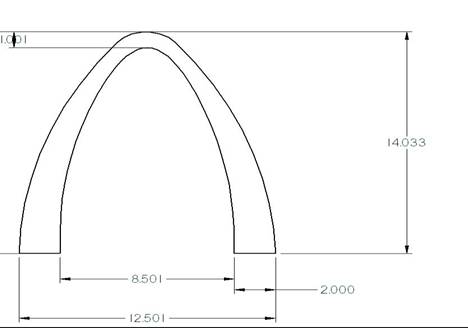

Another configuration was

analyzed to evaluate its stability. The height was increased and width

decreased. The actual dimensions are shown in Figure 3.21.

Figure

3.21. Taller design,

dimensions in feet.

On performing analysis on this structure it was seen

the funicular polygon lies inside the structure, making the structure stable.

3.22 shows the funicular polygon for this

configuration. Increasing the arch height usually improves

stability.

Figure 3.22. Funicular polygon of 60 bag taller, stable structure.

Erecting the MSFC Top-Connected Bag Arch

Only 46 of the 60 bags were needed when

building at MSFC. This size fitted within the construction space available,

achieved a sufficiently large structure for presentation, while shortening the

time to erect, and also demonstrating how the extra 14 bags could potentially

be used to serve as supplemental supports. Figure 3.23 shows a structure,

designed to be stable. Only 3 large bags were present as bottom bags. A wooden

frame in Figure 3.24 was constructed that served to guide erecting toward the

approximate catenary shape at 5 points, where pipes

were placed on the frame for the fabric to hang. Actual pipe locations can be

compared to design dimensions in the following the table. (Note that in the

top-connected bag arch, the pipes provide minimal support because of the

bending stiffness that this construction offers). 2x4’s attached to the bottom

and sides of the frame (not visible) served as the foundation, preventing the

bottom bags from slipping to the left or right.

Figure 3.23. CAD Model Template to

Guide Erecting

Table 3.1 Construction

details

|

POINT |

X

|

Y

|

Actual Pipe Locations |

|

A |

0 |

0 |

|

|

1 |

1.45 |

18 |

|

|

2 |

2.151 |

23.746 |

|

|

3 |

2.985 |

29.475 |

|

|

4 |

3.9 |

35.18 |

|

|

5 |

5.1 |

40.857 |

|

|

6 |

6.4 |

46.49 |

|

|

7 |

7.9 |

52.08 |

|

|

8 |

9.6 |

57.61 |

|

|

9 |

11.59 |

63.06 |

|

|

10 |

13.806 |

68.411 |

Lower Level Pipes: x=14.5”, y=70” |

|

11 |

16.31 |

73.63 |

|

|

12 |

19.129 |

78.687 |

|

|

13 |

22.29 |

83.536 |

|

|

14 |

25.817 |

88.127 |

2nd Level Pipes: x=25.7”,

y=88” |

|

15 |

29.724 |

92.399 |

|

|

16 |

33.56 |

95.88 |

|

|

17 |

38.66 |

99.73 |

|

|

18 |

43.65 |

102.65 |

|

|

19 |

48.913 |

105.087 |

|

|

20 |

54.39 |

106.955 |

|

|

21 |

60 |

108.287 |

Top Pipe:

x=60, y=108” |

Figure 3.24. Air-Filled 46 Bag Structure, 5 pipes guiding bag filling.

After airfilling the bags,

filling of bags with vermiculite proceeded from bottom bags up. Bags were filled

using a Flexible Screw Conveyor System (Hapman,

Figure 3.25: Bag Filling Process

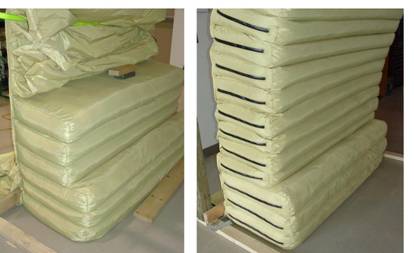

Lower bags were filled and

formed to a near rectangular shape (Figure 3.26), while trying to provide bag

angle (notice the black zippers) as the structure grew.

Figure

3.26. Rectangular Packed

Bags

Filling of the top 20 bags required a different

technique. Unfilled bags now hang down

from the top fabric, and cannot be filled with a rectangular shape and maintain

soil strength because of the looseness of the bag. Therefore the top 20 bags

must be filled to capacity with vermiculite, which causes them to round. With

the top three bags unfilled, the topmost filled bags were nearly touching,

which made it difficult to fill the top three bags. The maximum amount of

material that could be placed in a bag was restricted by the Helicoid Screw System, which was limited to a relatively

low compaction pressures because of the stiffness and strength limitations of

the relatively flexible and shaftless helicoid. Low compaction pressure contributed to the top

three bags not filling to the desired pressurs and

fullness. It was impossible to reach into the space and pack the bags by hand.

The final erected prototype is shown in Figure 3.27 (front view) and Figure

3.28(rear view). Note that in both views the pipes have been removed from their

2x4 supports, so the structure is standing without external support. We noticed

that the structure did settle ~2” once the top 3 pipe supports were removed.

Figure

3.27. Front View

Figure

3.28. Rear

View. Note the zippers.

Upon review of the standing structure and the process

of erecting, we noted the following:

- The

left side of the structure in Figure 3.27 (right side in Figure 3.28) is

the “good side”. It was built and maintained a catenary

shape very near design specifications, except for the topmost bags.

- The right side of the structure in Figure 3.27

(left side in Figure 3.28) is the “bad side”. Here we saw several flaws

that were a result of bags that were not filled to capacity.

- Figure 3.29a show that several bags on the bad

side with a flattened profile that lost the catenary-shape

curvature. Bags slipped downward despite our best attempts to erect the

structure with a catenary shape; bags slippage

was visible and occurred over a several second interval. Slippage is attributed to a shortage of

vermiculite due to incomplete packing, which did not occur on the good

side; the vermiculite grains may slide (shear) with respect to each other

inside the bags. This situation is

correctable (but difficult given that zippers are only on one end) by hand

loading more vermiculite through an open zipper and forcing material into

the bag with a plunger. A simpler fix would have been to have used an

auger-type system which deposits vermiculite under higher pressure than

the helicoid.

Figure

3.29. a. Upper left

photograph shows bags in a straight line, deviating from a caternary

shape. b. Lower left photograph show a bag that is tightly packed and bulging.

c. The upper right photograph show tightly packed 1’ bags on the good side; it

is difficult to insert a finger between the bags. d. The lower right figure shows loosely

packed bags on the bad side; the finger is easily inserted between the

bags.

4. Figure 3.29b

shows a tightly filled bag; it bulges and exhibits a hardness which can be felt

by applying finger pressure. Tightly filled bags are necessary to create bags

with sufficient vermiculite strength. Part of the internal bag pressure is a

result of loading from the bags above.

5. Figure 3.29c shows how another characteristic of a

well-built structure with tight bags. Here it is difficult to insert a finger

between the bags, implying that the bags are tightly packed with respect to

each other. Compressive and shearing loads are transmitted without failure

across the fabric boundary, from bag-to-bag.

6. Figure 3.29d shows a characteristic of inadequately

packed bags. Here it is easy to insert a finger between the bags – this may

imply the beginnings of hinge formation. The bags themselves are loosely packed

- by applying finger pressure the bags easily indented. The dark patch in the

figure represents glue that was placed in-between the bags as an experiment.

The glue did not appear to affect the structure. If the glue had affected the

structure, the glued fabric would have been in tension, and this was not the

case.

In summary, the top-connected bag structure is stable

if erected correctly - by filling the bags with sufficient pressure and

designing using masonry arch structural design principles. Several

recommendations and comments for future work are as follows:

- The

auger system used in our work was unable to fill the bags to sufficient

pressure. An auger with a central shaft would have provided higher

pressure and a more stable structure. It would have been convenient to

have had a method for easily “topping off” bags with vermiculite once the

auger was removed and filling was thought to have been complete. The top 3

bags were not filled to our satisfaction.

- We

can envision that other methods of erecting the structure are possible,

and simpler and more appropriate for erecting on the moon. Sensors could

be used to measure bag pressure and deviations of the shape from the

desired while erecting, so adjustments can be made. Shaping of bags during

and after filling was a challenging manual task.

- Analysis

can be greatly improved, by incorporating both fabric and regolith

materials and their characteristics in the analysis, perhaps using

nonlinear finite element analysis. Improved analytical methods could be

used to optimize the design. Regolith and vermiculite soil strength

parameters (determined by standard soil mechanics tests or the Lunar

Sourcebook) need to be incorporated into the modeling, along with fabric

strength parameters.