Technical Services

We deliver excellent technical services to the industry which include:

Lab testing including cross-checking and calibrations

Fiberline audit, troubleshooting and optimization

Contract research

Technical training

Technology transfer and implementation

We also offer a range of testing services to the pulp and paper and allied industries which may involve students from our program to get experience in these industry aligned research and testing projects.

Pulp and Paper processing and Testing Laboratories

In Alabama Center of Paper and Bioresources Engineering in addition to (A) a professional-scale testing services, we have (B) the capability to perform a lab-scale processing of pulp and paper, and (C) other testing capabilities.

(A) Testing Capabilities:

For Physical Testing, we have the following equipment and methods:

Tensile strength is the maximum tensile force developed in a test specimen before rupture on a tensile tester carried to rupture under prescribed conditions. Tensile Tester (L&W ALWETRON TH1) is a horizontal type tensile tester designed for testing of paper and low elongation films and foil. Output results are paper strength in force units (standard or metric), elongation at break as a percent from the original gauge length. Tensile strength given is the force per the width of test specimen, which is 1 inch, usually |

|

Tensile Tester (TMI Monitor) is a vertical single-column tensile tester designed for testing of paper and low elongation films and foil. On this machine, we can change sample width, gauge length, pretention and loading rate. Output results are paper strength in force units (standard or metric), elongation at break as a percent from the original gauge length. TAPPI T494 - Tensile properties of paper and paperboard (using constant rate of elongation apparatus) ASTM D 828 - Tensile Properties of Paper and Paperboard Using Constant-Rate-of-Elongation Apparatus |

|

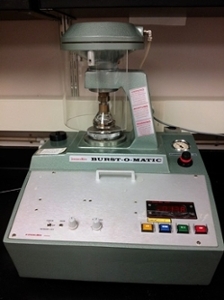

Bursting strength is the maximum pressure required to rupture the tested material. The sample is held at the perimeter while the hydrostatic pressure is increased at a controlled constant rate under a rubber diaphragm until sample rupture. The L&W Burst-o-matic is designed to measure the bursting strength of sheet materials. Output results are paper burst strength in pressure units (standard or metric), commonly psi TAPPI T403-Bursting strength of paper TAPPI T807-Bursting strength of paperboard and linerboard TAPPI T810-Bursting strength of corrugated and solid fiberboard ASTM D774/D774M – Bursting Strength of Paper |

|

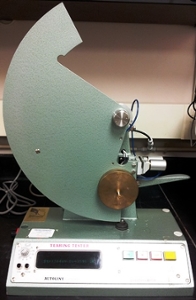

The energy consumed to tear the test sample (usually 4 plies of the sheet material) a certain distance is used to calculate the average tearing force. The L&W Tearing Tester measures the tearing strength of paper, fabric, plastic foil, ect. The tearing energy is measured through positional change of machine’s pendulum. Output results is the paper tearing strength in force units standard or metric (usually pounds). TAPPI T414-Internal Tearing resistance of Paper (Elmendorf type) ASTM D 689 – Internal Tearing Resistance of Paper |

|

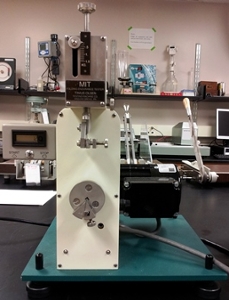

A strip of sheet (paper) under a standard tension is subjected to double folding oscillations until break. The logarithm to the base 10 of the number of double folds is considered as “Folding Endurance”. It measures the ability of paper to withstand repeated folding. It is also useful for indicating the deterioration of material upon aging. TAPPI T511-om-02-Folding endurance of paper (MIT tester) ASTM D 2176 – 97a R02 -Folding Endurance of Paper by the M.I.T. Tester |

|

A strip of sheet (paper) is clamped in two pair of clamps 0.7 mm apart. moving towards each other, sample is compressed in the edge direction. The maximum force causing failure is measured and given in pound. The L&W Compression Strength Tester uses the STFI method of testing for edgewise compression strength of containerboard in the range of 100 – 400 g/m2. TAPPI T826 - Short span compressive strength of containerboard |

|

The L&W Stiffness Tester is used to evaluate stiffness and resiliency properties using resonance length TAPPI T535 - Bending stiffness of paper and paperboard-Resonance length method |

|

This instrument measures the bending moment required to deflect the free end of a 1.5 in wide vertically clamped specimen 15º from its center line when the load is applied 2 in. away from the clamp. The resistance to bending is calculated from the bending moment and given in Taber units. TAPPI T489-Bending resistance (stiffness) of paper and paperboard (Taber-type tester in basic configuration) |

|

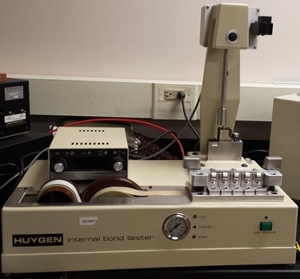

The Huygen Internal Bond Tester is designed to measure rapid “Z” directional ruptures of paper and paperboard samples. The unit uses Scott and American Sisalicraft specimen technique. TAPPI method: T569 - Internal bond strength (Scott type) |

|

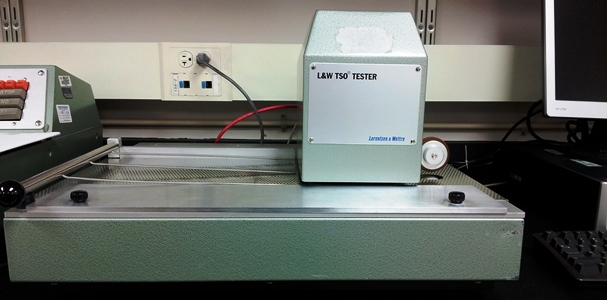

The TSO Tester is an ultrasonic instrument for measuring Tensile Stiffness Index or Tensile Stiffness Orientation properties on sheets and cross machine paper samples. |

|

The L&W Crush Tester is used for testing liner, fluting, corrugated fiberboard, packaging, and similar products. |

|

Gurley is the standard instrument for measuring porosity, air permeability, or the air resistance of paper products. TAPPI T460-Air resistance of paper (Gurley method) TAPPI 536 om-02 Resistance of paper to passage of air (high-pressure Gurley method) ASTM D 726 – 94 (Reapproved 2003) Resistance of Nonporous Paper to Passage of Air |

|

The Hagerty Paper Smoothness Tester tests the surface smoothness of paper especially coated. This method is a measurement of the air flow between the specimen (backed by flat glass on the bottom side) and two pressurized, concentric annular lands that are impressed into the sample from the top side. The rate of air flow is related to the surface roughness of paper or paperboard. TAPPI T538 - Roughness of paper and paperboard (Sheffield method)

|

|

The Glossmeter provides 75⁰ and 20⁰ specular gloss measurements Its primary application is for coated papers but the machine may also be used on uncoated papers, most ink films, and paper or paperboard. TAPPI T480 Specular gloss of paper and paperboard at 75 degrees TAPPI T653 Specular gloss of paper and paperboard at 20 degrees |

|

The Brightimeter Micro S5 measures brightness, opacity, color, and fluorescence. TAPPI T425, Opacity of paper (15/d geometry, illuminant A/2°, 89% reflectance backing and paper backing) TAPPI T452, Brightness of pulp, paper, and paperboard (directional reflectance at 457 nm) TAPPI T524 - Color of paper and paperboard (45/0, C/2) TAPPI T562 - Brightness of pulp, paper, and paperboard (directional reflectance at 457 nm) CIE whiteness and tint of paper and paperboard (using 45°/0° directional illumination and normal viewing) TAPPI T646 - Brightness of clay and other mineral pigments (45/0) ASTM D985 – Brightness of Pulp, Paper, and Paperboard (Directional Reflectance at 457 nm) |

|

|

The Electronic Micro Gauge measures specimen thickness within the 0 – 3 mm range. TAPPI T411-Thickness (caliper) of paper, paperboard, and combined board ASTM D645/D645M - Thickness of Paper and Paperboard |

|

Methods

We have the capabilities to perform the following TAPPI and ASTM methods:

TAPPI T401-Fiber analysis of paper and paperboard

ASTM D1030 - Fiber Analysis of Paper and Paperboard

TAPPI T227 - Freeness of pulp (Canadian standard method)

TAPPI UM256 - water retention value (WRV)

TAPPI T221 - Drainage time of pulp

TAPPI T230 - Viscosity of pulp (capillary viscometer method)

TAPPI T410 - Grammage of paper and paperboard (weight per unit area)

TAPPI T211 - Ash in wood, pulp, paper and paperboard: combustion at 525°C

TAPPI T413 - Ash in wood, pulp, paper and paperboard: combustion at 900'C

ASTM D586 – Ash in Pulp, Paper, and Paper Products

ASTM D644 – Moisture Content of Paper and Paperboard by Oven Drying

TAPPI T402 - Standard conditioning and testing atmospheres for paper, board, pulp handsheets, and related products

ASTM D685 – Standard Practice for Conditioning Paper and Paper Products for Testing

(B) Processing of pulp and paper Capabilities

wood chip Cooking (Kraft Pulping)

T200-96 -Laboratory beating of pulp (valley beater method)

T205 95 Forming handsheets for physical tests of pulp

T220 96-Physical testing of pulp handsheets

T236·99·Kappa number of pulp

T240 93-Consistency (concentration) of pulp suspensions

(C) Other Capabilities

In our wet processing and testing laboratory, we have a whole line of machines from wood chip digesters, pulpers, repulpers, mixers, to handsheet paper making. Recently, we added to our lab a pilot scale Microfluidizer M-110EH-30. This machine adds to our capabilities to produce NFC (Nanofibrillated Cellulose) or MFC (Microfibrillated Cellulose) fibers that can be used in many applications.

|

The M-110EH-30 Microfluidizer Processor uses interchangeable chambers of varying geometries to process a range of fluids such as fiber suspensions in multiple passes to break the fibers down to a micro or nano scale. |

|

|

|

|

The Paprican Ink Scanner measures the speck count to assess the dirt level in secondary fiber pulps. |

|

For additional infomation please contact:

Ramsis Farag

Testing Services Manager

334-444-0655