Researchers earn $2.5 million Department of Energy grant to convert polluted waste into aquafeed

Published: Dec 11, 2024 3:40 PM

By Joe McAdory

Peter He and a team of researchers are developing novel technology that converts pulp and paper mill flue gas (carbon emissions) and aquaculture wastewater into algae-based protein for aquafeed pellets.

In short, they’re turning pollution into fish food.

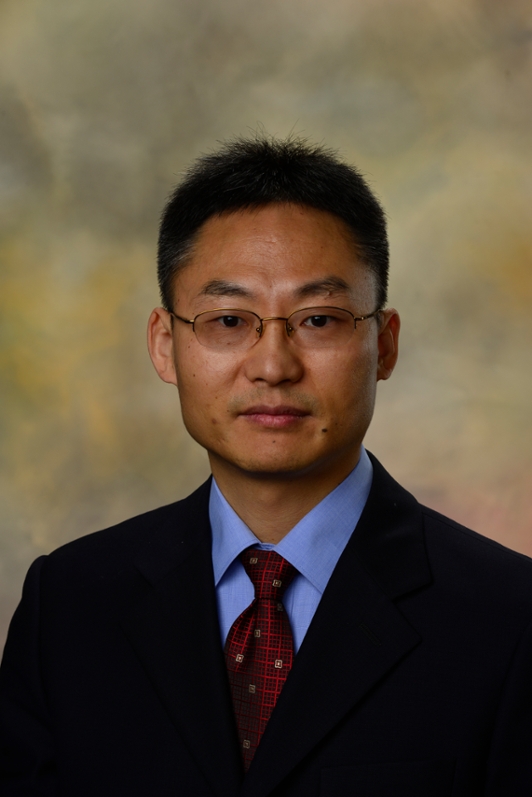

He, the Uthlaut Endowed Professor in the Department of Chemical Engineering, is principal investigator (PI) on the U.S. Department of Energy (DOE)-funded, $2.5 million (~$3.2 million with cost share) project, “Intensified and Energy Efficient Cultivation, Processing, and Conversion of Flue Gas Produced Algal Biomass to Aquafeed.”

“We believe that we can reduce harmful wastes from both pulp & paper and aquaculture industries and turn them into something useful,” He said. “As the population increases, the demand for protein will increase. One means to produce protein is through aquaculture, which has the greatest overall efficiency compared to other animal production systems. To achieve a circular aquaculture, converting waste into aquafeed is very important.”

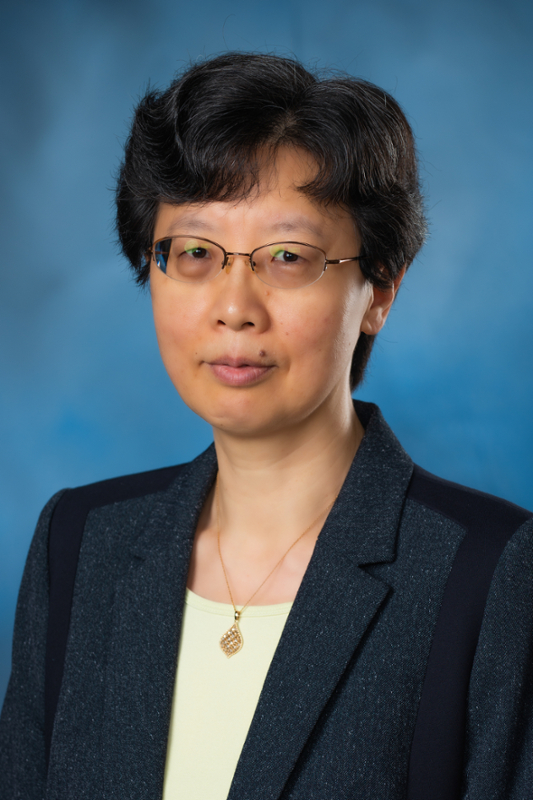

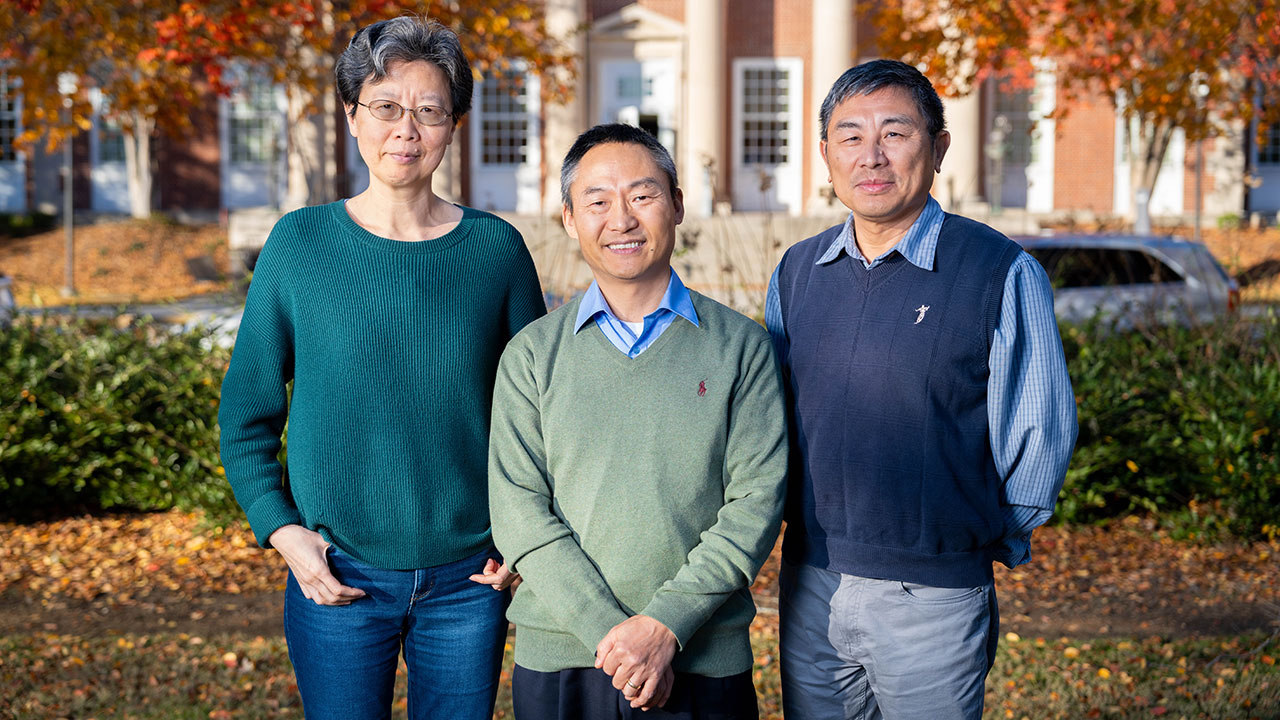

Part of a multi-university/industry DOE initiative aimed at advancing mixed algae developments for low-carbon biofuels and bioproducts, He is joined by peer co-PIs from Auburn, Jin Wang, the Woltosz Professor of Chemical Engineering, Zhihua Jiang, the Auburn Pulp and Paper Foundation Associate Professor of Chemical Engineering, and Allen Davis, professor at the Auburn University School of Fisheries, Aquaculture & Aquatic Sciences.

Other co-PIs include Shamin Begum, associate professor in chemical engineering at Tuskegee University, Ling Tao of the National Renewable Energy Laboratory, Ray Shirley from the Packaging Corporation of America and Stephen Dvorak from DVO Inc.

The project aims to significantly enhance current algae cultivation technologies by increasing productivity by 200%, boosting biomass concentration by 300%, and reducing production costs by 50%. Besides directly capturing carbon dioxide from flue gas and converting it into algae, the utilization of algae as aquafeed further boosts greenhouse gas emission reduction.

Success of this project, He said, relies on three key innovations:

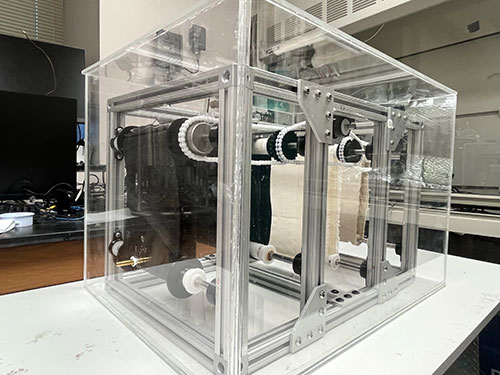

* Using dry microalgae biofilm as biocatalysts to intensify the flue gas conversion process and improve biomass productivity.

* Adapting advanced and energy efficient pulp and paper dewatering and drying techniques for algae dewatering and drying.

* Systems engineering approaches that employ feedstock integration, logistic integration, process integration and energy/heat integration.

“Various studies have demonstrated that biofilm-based microalgae cultivation has many advantages over raceway ponds and conventional photobioreactors,” He said. “One key innovation of our solution is the dry biofilm. By making biofilm dry, the transport of carbon dioxide to the biocatalyst will be significantly enhanced, therefore improving carbon dioxide uptake and biomass productivity.”

The project will divide specific tasks among the researchers.

He and Wang will optimize and quantitatively assess algae productivity in a 104-liter lab-scale dry biofilm photoreactor using flue gas and aquaculture wastewater. This is expected to fine-tune the technology and optimize the operation parameters.

Researchers will move to a greenhouse-style 1,000-liter prototype, to be developed by DVO, for pilot testing at the Auburn University Fisheries.

Jiang, who also directs the Alabama Center for Paper and Bioresource Engineering, will test, optimize and compare different dewatering techniques on microalgae in his laboratory to significantly improve algae harvesting in economic and sustainability metrics.

Davis' lab will oversee the evaluation of the aquafeed ingredients’ nutrient profile, safety and efficacy for potential commercial aquafeed applications.

The project is expected to require two years of intensive research and development activities, and effective communication and active participation among collaborators.

“Creating algae-based aquafeed is crucial not only for sustainable aquaculture but also for reducing our environmental footprint,” He said. “By utilizing waste products, like emissions from paper mills and wastewater, and converting them into valuable resources, we are actively contributing to a healthier planet. It's incredibly rewarding to know that our work not only supports the environment but also plays a significant role in ensuring food security for future generations.”

Media Contact: , jem0040@auburn.edu, 334.844.3447

From left, Jin Wang, Peter He and Zhihua Jiang.