Equipment

The ICAMS manufacturing facility is located at 1490 Pumphrey Ave., Auburn, AL.

Quick Links:

Subtractive Manufacturing:

- Mazak VTC-300

- DMG Mori

- Okuma M460-VE

- Haas UMC-750SS

- Hurco VMX42SRTi

- Hurco TMX8MYSi

- Tsugami B0326-III

- Haas TM2

- Haas TL2

- Universal Robots UR10e Co-bot

Additive Manufacturing:

Electrical Discharge Manufacturing:

- Wire EDM CUT E600

- Plunge EDM

Waterjet:

Grinding and Laser Engraving:

- Chevalier Grinder

- Dominator 20PF-LMT

Welding:

Legacy:

CMM, Metrology, and Microscope:

Load Frame:

- MTS Load Frame

Sensors:

Brand: Mazak

Model: VTC-300C

Type: Vertical Machining Center with High Torque Capability

The Mazak VTC-300C is ICAMS most rigid machine and has the largest work area. It is perfect for fabrication of large parts that require precise work performed. Its machining table is 2000mm by 760mm. This machine is also designed to handle extra load to the machining table and the spindle torque load. Maximum spindle RPM is 15000 and can operate under its maximum loaded state for up to 10 minutes. This allows for the Mazak to perform friction stir welding operations in addition to its 3-axis machining operations. Our VTC-300C is also outfitted with a rotary table and tail stock that has expanded our operational capabilities to include some 4-axis operations.

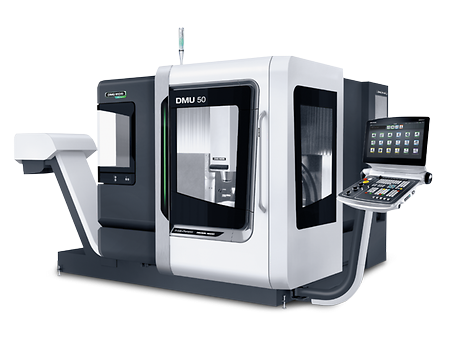

Brand: DMG Mori

Model: DMU 50 / Power Clamp / Microset

Type: Siemens 5-Axis CNC Operations Cell

This operations cell is used as a demonstration of the Siemens software solutions for a 5-Axis machining Cell. The Celios user interface used on the DMU 50 is one of the most user-friendly CNC HMI systems available. This is one of our available 5-Axis machines, and with its highly rigid frame boasts a great degree of accuracy. The Power Clamp allows for the use of shrink fit tool posts for even greater precision. The Microset uses precision visual measurements to find exact tool dimensions. The Siemens operation cell is an example of precision machining in the manufacturing industry.

Brand: Okuma

Model: M460-VE

Type: 3-Axis CNC

The Okuma M460-VE is a 3-axis milling machine intended for the machining of simple prismatic prototypes and the preparation of stock material for 5-axis machining. The Okuma also offers an open-ended control system named OSP-300 that allows for the download of applications that further enable the machine with features such as Machine alerting and MTConnect monitoring. The Okuma M460-VE boasts a maximum spindle speed of 15,000 RPM, a 30-tool automatic tool changer, and uses compressed air cooling for research purposes. This machine is also outfitted to utilize the stationary and rotating dynamometers that are used in cutting force research at ICAMS.

Brand: Haas

Model: UMC-750SS

Type: 5-Axis CNC Mill

This machine utilizes Haas Next Generation Control for B (120⁰- -35⁰) /C (360⁰) Table 5 axis milling. Available features include, limited MTConnect data extraction, TSC (Through Spindle Coolant), Flood Coolant, 15,000 rpm spindle capacity, 40 tool side carousel, part probing, tool probing, and a machining capacity of < 30” X, < 20” Y, and < 18” Z.

Brand: Hurco

Model: VMX42SRTi

Type: 5 Axis CNC

This 5 Axis CNC machine operates on the WinMax software that has recently been standardized across all Hurco production level machines. It operates with A and C rotary Axis and has a machine travel limit of 42 in x 20.5 in x 24 in. The VMX42Ui can operate at up to 12,000 RPM and can reach a peak torque of up to 176 Nm for up to a minute. The VMX42Ui can hold up to 40 tools in its tool turret and handles a maximum tool diameter of 3 in with a length of 11.8 in. Tool weights cannot exceed 15.4 lb.

Brand: Hurco

Model: TMX8MYSi, HB65-1.5

Type: Turning Center with Live Tooling and Bar Feeder

This turning center is one of the most advance turning centers in the state of Alabama and offers turning on a main and sub-spindle, live tooling capable of up to 1” end mills, as well as automation features such as a parts catcher, a bar feeder, and a machine tending collaborative robot. The main spindle can reach up to 5,000 RPM and can be used synchronously with the sub spindle for a more rigid setup when machining small diameter features. The tooling turret can hold 12 tools and is rated for up to 5000 RPM for end mills that can machine the radial and axial surfaces of the part for complex geometries. The bar feeder that is installed with the machine can load up to 6 bars at 4’ in length from 1” to 2” diameters that can support production in the machine for multiple production shifts.

Brand: Tsugami

Model: B0326-III Laser Swiss State of the Art Swiss Turning Center

Type: Laser Hybrid Turning Center

The Laser Swiss turning center allows for very detailed work on very small and intricate components. As a turning center it allows for both lathe work and mill work to be performed on the part without needing to remove it from the workholding. The main spindle has a max speed of 8,000 rpm with a max live tooling speed of 6,000 rpm. The maximum part diameter is approximately 1 ¼ ins. The Laser Swiss system uses gang tooling to store its tools and to perform its tooling operations. When extremely small features are required, the laser installed in the machine is capable of removing walls up to 3mm thick with a precision focused diameter of 0.015 mm. This is perfect for slots, grooves, pin holes, and other required small patterns.

Brand: Haas

Model: TM2

Type: 3-Axis CNC Mill

Standard 3-Axis CNC for research purposes only. Features spindle speed of 4,000 rpm, work envelope of 40” X, 16” Y, and 16” Z, and an A Rotary table attachment with 360⁰ of rotation.

Brand: Haas

Model: TL2

Type: CNC Lathe

Standard CNC Lathe for research purposes only. Features 10 hp (108 ftlb of torque) spindle with max speed of 1,800 rpm, work envelope of 8” X and 48” Z.

Brand: Universal Robots

Model: UR10e Co-bot

Type: Collaborative Robotic Arm

The UR10e is a collaborative robot arm used for machine tending on the Hurco turning center and the Hurco 5-axis mill systems. These robots enable the automation of these manufacturing systems with ease thanks to the intuitive user interface and “pick & place” programming routine. Typically, robotic arm technology takes a high-level FANUC based programmer, but with a collaborative robot the user can "teach” the robot the movement by moving the robot by hand to the desired locations for production. These robots have a reach of 51 inches, can hold up to 28 pounds, and come with a pallet system to keep a manufacturing cell running for a full shift with no outside interference.

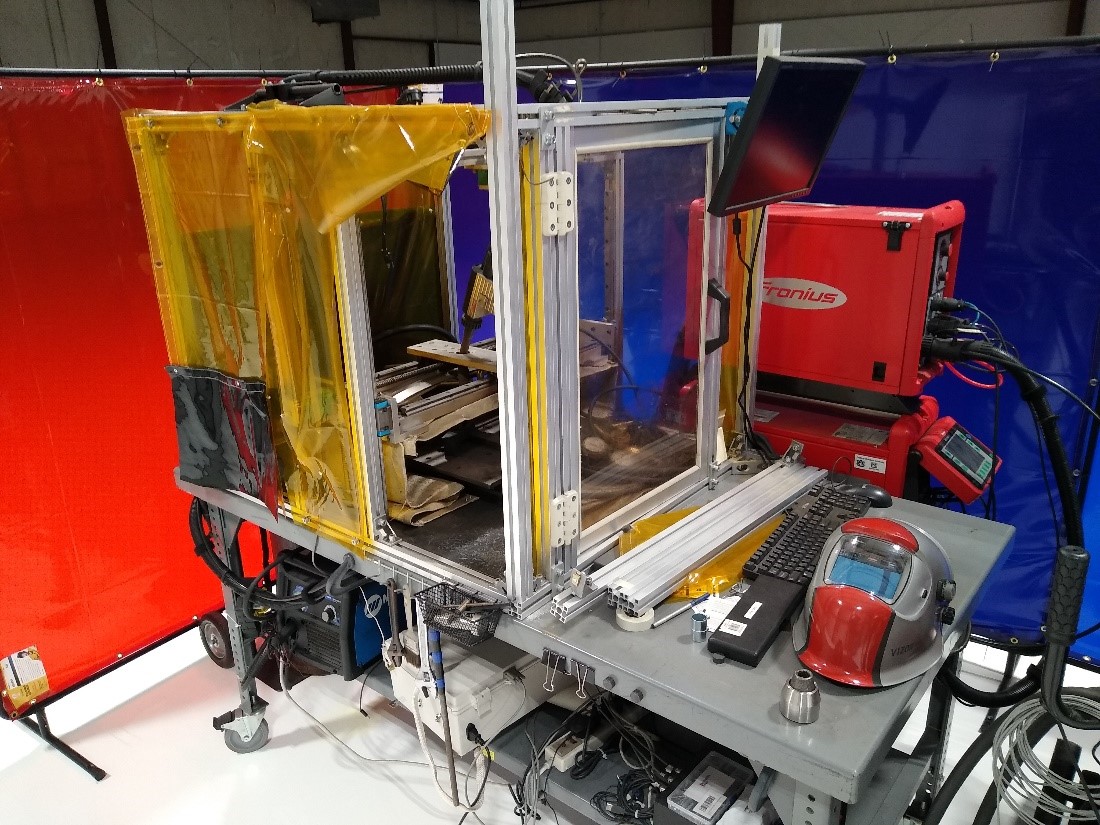

Brand: Auburn University / FRONIUS

Model: Custom WAAM Printer / CMT Welder

Type: 3 Axis with CMT Welder

This Wire Arc Additive Manufacturing (WAAM) System uses cutting edge Cold Metal Transfer welding systems and MACH software to produce metal additive manufactured parts. This is a custom build produced by prior graduate researchers at Auburn University and continues to be the focus of ongoing research into WAAM geometry fabrication solutions and control scheme solutions. Prior research has already validated the mechanical properties of the produced parts and has optimized various tool pathing processes. Several custom control schemes have already been implemented and future work is planned to improve and optimize the print production time.

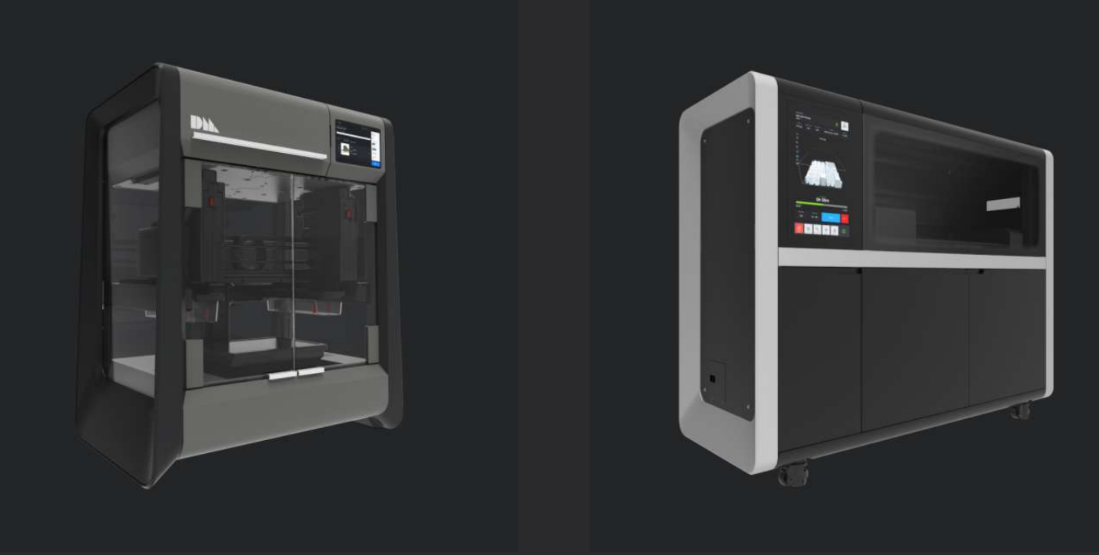

Brand: Desktop Metal

Model: Studio System 2 Printer and Shop Printer

Type: Metal Prototyping and Production Printer Cell

These two systems offer the variety to print with either a powder bed or bound powder metal extrusion printing system. The powder bed Shop Printer can produce a large quantity of parts in its expansive build volume by binding the powder together with a binding agent. This system is optimal for small to medium production runs of parts with complex geometries. The Studio System uses a binder + metal powder extrusion with a binding agent to rapidly produce prototypes. These prototypes produced with the studio system require binder expunging from the part rather than oven bake out required for the Shop System. The Shop Printer system has a higher resolution for part production but will take longer to produce compared to the Studio System printer.

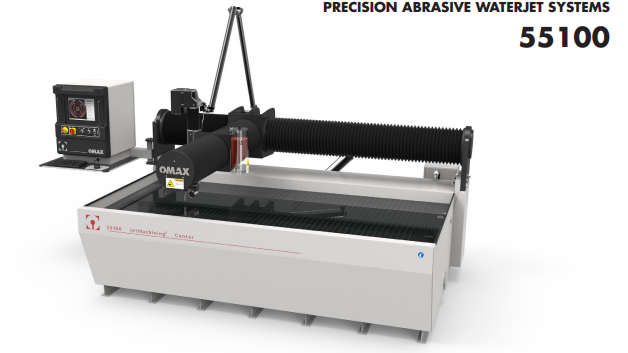

Brand: OMAX

Model: 5500

Type: Water Jet

The OMAX 55100 is a swivel-head water jet with a rotary table that has more than an 8’ x 4’ work envelope and has the power to cut through 6” thick aluminum with a linear speed of 12 inches per minute. The system uses DXF or CAD drawings to quickly create cutting paths, which makes it excellent for sheet metal fabrication. This water jet also comes with a swivel-head to compensate for the taper produced by the water stream as well as a rotary table to enable the cutting of tubing in a polar coordinate system.

Brand: Bridgeport, Sheldon, Grizzly, WellSaw, Seiki

Model: Manual Mills, Lathes, Saws, Grinders, Polishers, and Sand Blasters

Type: Manual Machining Cell

ICAMS has a collection of manual machines that allow us to perform any stock prep that might be necessary in our operations and production runs. These machines allow us to replace and repair simple mechanical parts and prepare stock for CNC usage. We also are able to apply the desired surface finish to machined parts using one of our finishing options. ICAMS is also in the process of instrumenting this legacy machines to integrate them into our Industry 4.0 digital loop.

Brand: Lincoln Electric

Model: Welder

Type: Multi Action (MIG, TIG, Stick)

These welders are used with our smaller welding tables or larger fabrication table to accomplish any welding needs that may arise at ICAMS.

Brand: Cobalt

Model: Dominator 20PF-LMT

Type: Mopa Laser Marking System

The Cobalt Dominator allows us to do marking and engraving on metal surfaces. This allows us to serialize production or add customizations and logos to parts that we produce. It has a maximum work area that varies based on the lens used but the areas range from 2” x 2” to 6.89” x 6.89”. The lasers are strong enough to remove material from aluminum and to etch and change the color of steels.

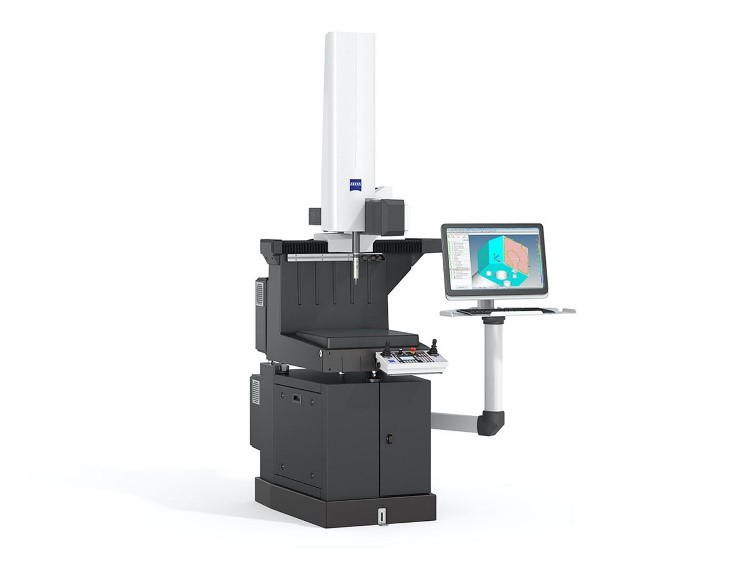

Brand: Zeiss

Model: DuraMax and Contoura

Type: Coordinate Measuring Machine

These systems are both high precision measurement machines. These machines use a variety of probes that physical make contact with the part and evaluate the exact dimensions of the features present on the part. These evaluations can be consolidated into a report for easy review of part quality. Any identified issues can then be addressed. The Contoura in addition to its tactile probes has a Dot Scan system that optically evaluates the part dimensions. The calypso software from Zeiss is used across both machines and allows for easy adoption of measurement plans from our DuraMax to our Contoura.

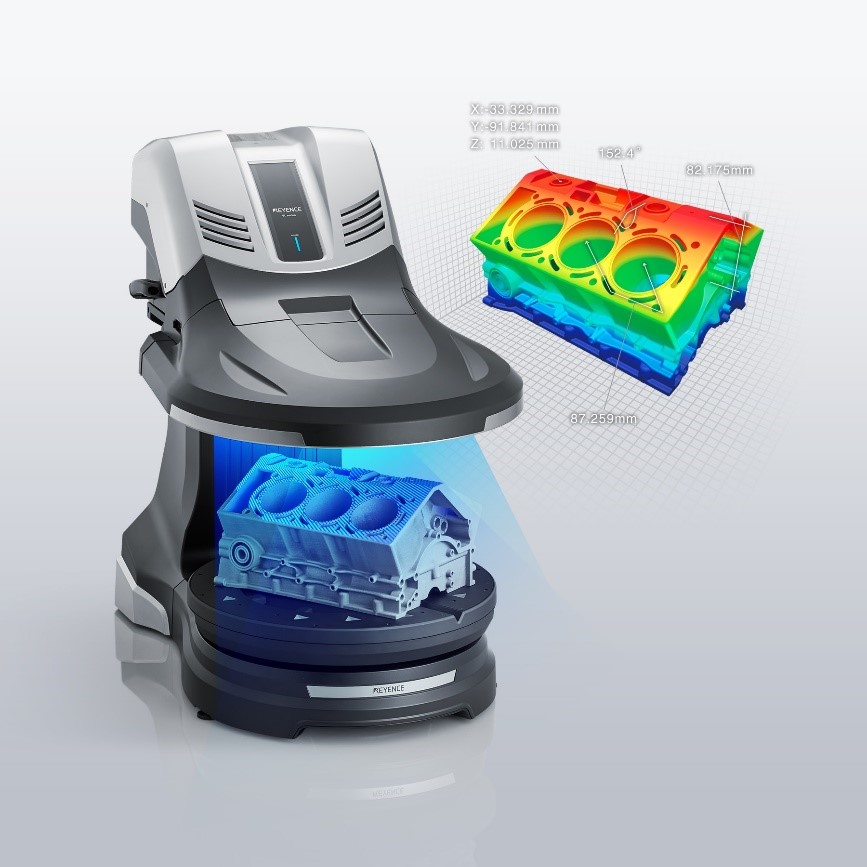

Brand: Keyence

Model: 3D Scanner CMM VL Series

Type: 3D Scanner

ICAMS’s Keyence scanner allows us to scan in complex geometries that may be too advanced for use on our other CMM systems. We can then compare the scan to a CAD model and evaluate for any discrepancies and address any manufacturing issues identified at that time. The Keyence also has the functionality to export a 3D scan as a mesh that can be opened and modified in other CAD software. This allows us to reverse engineer components and solve problems that local industrial partners may be facing.

Brand: Kistler

Model: 9273 and 9257A

Type: Plate and Torque Dynamometers

These Kistler piezoelectric dynamometers can measure X, Y, Z forces up to 5,000 N, as well as torque about the Z axis up to 200 N*m. These are fixed dynamometer that the workpiece is mounted to, and any forces of interest are applied to the workpiece. They are primarily used at the ICAMS facility to conduct cutting force testing but can be used for a much wider range of applications. By measuring the forces or torque during a milling, turning, or drilling process, the process can be better understood and can lead to the optimization of tool life, surface finish, and overall machining efficiency.

Brand: Kistler

Model: 9171A

Type: Spindle Dynamometer

This spindle mounted Kistler piezoelectric dynamometer can measure X, Y, and Z forces up to 20,000 N and torque on the spindle axis up to 1,000 N*m. Besides the larger range of measurement when compared to the fixed dynamometers, the advantage of the spindle mounted dynamometer is that it can measure the forces and torque on the tool directly, which gives more insight to things like tool wear and direct mechanical loading on the tool during the cutting process. This device also has a very high dynamic range such that frequency analysis can be performed in situ the cutting process using modal analysis.

Brand: FLIR

Model: A655SC (With FOV Lens Options)

Type: Thermal Camera

The FLIR A655SC is a thermal camera with a 640x480 resolution and a default capture rate of 50 Hz. At windowed resolutions it has the ability to capture images at a rate of up to 200 Hz. The camera uses automatic focusing and with a variety of Field of View lens options available, the camera can capture a large or small area for recording of surface temperatures. The FLIR A655SC has default temperature range of –40°C to 150°C and 100°C to 650°C, but it has the capability to record up to 2000°C with its optional settings. This is perfect for recording everything in manufacturing from the residual heat of metal cutting to the molten pools from a weld.

Brand: Photron

Model: FASTCAM Mini AX50

Type: High-Speed Camera

The Photron FASTCAM Mini AX50 is one of the highest performing small sized high-speed cameras, making it great for capturing high-speed footage in any setting. This camera boasts 2,000 fps capture for 1024 x 1024 pixels and up to 170,000 fps capture, all in the size envelope of a 5” cube at no more than 4 pounds in weight. This camera also has excellent light sensitivity, and a global electronic shutter that can be set at 1-nanosecond exposure. A KC VideoMax long distance lens has been paired with this camera to enable the recording of very small regions of interest, such as in the investigation of chip formation in metal cutting.

Brands: Arduino, Beaglebone, & Raspberry Pi

Type: Micro Controllers and Minicomputers

ICAMS works with a range of minicomputers, microcontrollers and PLCs to enable Industry 4.0 practices in the manufacturing workspace. These are paired with an even wider range of sensors to allow the monitoring and recording of systems on the shop floor such as Legacy machine operation, humidity control, Coolant acidity, and many other applications. These minicomputers can enhance the understanding of processes occurring on the shop floor and can enable more informed decisions and predictive maintenance on various manufacturing systems. ICAMS also demonstrates the use of an “All in One” minicomputer system named LIMS that can connect to any machine on the shop floor network as well as connect via simpler communication methods to the minicomputers, PLCs, or sensors used to monitor machines in the manufacturing workspace.

Brand: GF Machining Solutions

Model: CUT E600

Type: Wire EDM

A Wire EDM (Electrical Discharge Machine) is a precision machining tool used for creating intricate and accurate cuts in conductive materials by employing a thin wire as an electrode. It operates by discharging electric sparks between the wire and the workpiece, eroding material with remarkable precision while exerting no mechanical force. This non-contact machining process makes wire EDM ideal for crafting complex geometries and delicate parts in hard-to-machine materials.

The GF Machining Solutions CUT E600 at ICAMS stands out as a cutting-edge model with advanced 5-axis capability, enabling highly intricate cuts across multiple planes. This versatility makes it perfect for producing components with complex contours and precise dimensions, catering to industries with stringent quality demands. Additionally, its high-speed cutting, superior accuracy, and reliable automation ensure optimal performance and efficiency in high-tech manufacturing applications.

Brand: GF Machining Solutions

Model: FORM E600

Type: Plunge EDM

A Plunge EDM (Electrical Discharge Machine) is a high-precision tool used for machining complex cavities, intricate shapes, and hard-to-machine materials by using a shaped electrode to erode material through controlled electrical discharges. Unlike wire EDM, plunge EDM is ideal for creating deep cavities, molds, and dies with exceptional accuracy and surface finish. This non-contact machining process minimizes mechanical stress, making it ideal for delicate and high-precision components.

The GF Machining Solutions FORM E600 at ICAMS is a cutting-edge 4-axis plunge EDM designed for exceptional precision and reliability. Its 4-axis capability allows for the machining of intricate geometries and angled surfaces, making it highly versatile for complex projects. Engineered for demanding applications, the FORM E600 ensures excellent surface finishes, precise control, and efficient performance, making it a trusted solution for industries like aerospace, medical, and mold-making.

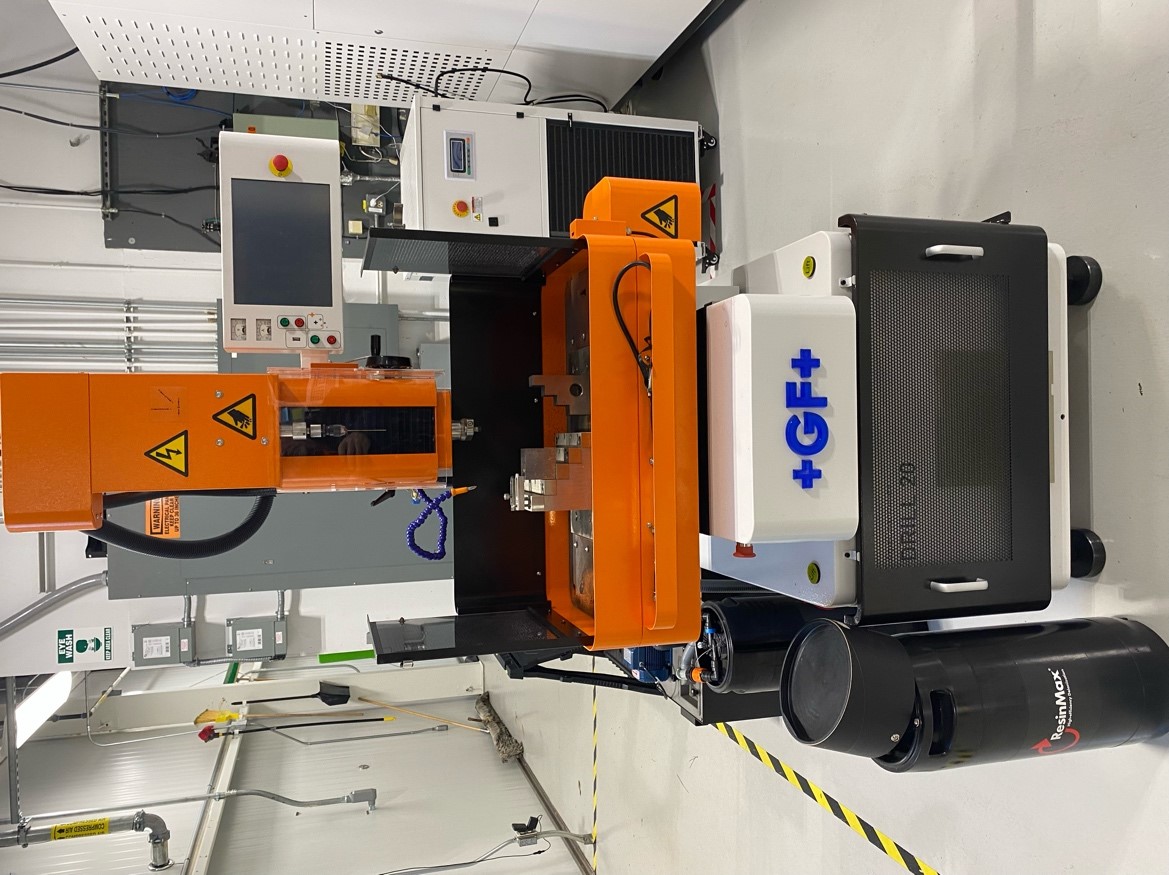

Model: Drill EDM 20

Type: Drill EDM

An EDM Drill is a specialized electrical discharge machining tool designed for creating precise, small-diameter holes in hard or conductive materials. It uses high-frequency electrical discharges and a rotating tubular electrode to efficiently drill deep, narrow holes with exceptional accuracy. This process is ideal for applications requiring micro-holes, such as cooling channels in turbine blades, wire threading starter holes, and fuel injector components.

The GF Machining Solutions Drill EDM 20 at ICAMS is a high-performance machine built for precision and reliability. It excels in creating small, deep holes with tight tolerances and smooth finishes, even in challenging materials like hardened steel or carbide. Compact yet powerful, the Drill EDM 20 is an essential tool for industries demanding precision drilling, such as aerospace, automotive, and energy production.

Brand: Keyence

Model: VR-6100

Type: Optical Profilometer

An optical profilometer is a non-contact metrology tool used to measure surface profiles, roughness, and dimensions with high precision. It utilizes advanced optical scanning technology to generate 3D surface maps, enabling detailed analysis of material textures and geometries without damaging the sample. This technology is ideal for industries requiring accurate surface characterization, such as manufacturing, research, and quality control.

The Keyence VR-6100 at ICAMS is a state-of-the-art optical profilometer designed for fast, accurate, and comprehensive surface measurements. Its ability to capture high-resolution 3D data across a wide range of materials and geometries makes it indispensable for ensuring product quality and optimizing manufacturing processes. With its user-friendly interface and rapid measurement capabilities, the VR-6100 enhances productivity while delivering precise and reliable results. The microscope has a 200X optical magnification.

Brand: Keyence

Model: VHX-S750E

Type: Microscope with Elemental Analysis

A microscope with elemental analysis is a powerful tool used to examine materials at the microscopic scale and determine their chemical composition. It provides detailed insights into both the structural and elemental properties of a sample. This combination of high-resolution imaging and elemental analysis is critical for industries that require precise material characterization, failure analysis, and quality assurance.

The Keyence VHX-S750E Microscope with Elemental Analysis at ICAMS is an advanced imaging system designed for ultra-high resolution and in-depth material analysis. It seamlessly integrates 3D imaging and elemental analysis, allowing for the accurate inspection of fine details and the identification of material composition. This microscope is a valuable tool for industries such as electronics and materials research, providing critical data for product development, quality control, and troubleshooting. The microscope at ICAMS will magnify up to 6000X optically.

Brand: Hitachi

Model: S-2460N

Type: Scanning Electron Microscope

A Scanning Electron Microscope (SEM) is an advanced imaging tool that uses a focused electron beam to scan a sample’s surface, creating highly detailed, high-resolution images of its morphology and structure. Unlike traditional optical microscopes, SEMs provide much greater depth of field and magnification, revealing fine details at the microscopic and nanoscopic levels. SEMs are critical for industries requiring surface analysis, such as materials science, failure analysis, and semiconductor inspection.

The Hitachi S-2460N Scanning Electron Microscope at ICAMS offers high-resolution imaging and excellent surface detail, making it ideal for a wide range of applications in research and quality control. Whether for evaluating microstructures, conducting failure analysis, or inspecting coatings, the S-2460N provides accurate, reliable results, enhancing the quality of production and research efforts.

Brand: Chevalier

Model: FSG-1224ADIV

Type: Grinder

A grinder is a precision machine tool used to achieve high levels of surface finish and dimensional accuracy on workpieces by utilizing a rotating abrasive wheel. It can be employed for various operations, including flat, cylindrical, and contour grinding, to produce smooth surfaces and tight tolerances. Grinders are crucial in industries where fine surface quality and high precision are required, such as automotive, aerospace, and tooling.

The Chevalier FSG-1224ADIV Grinder at ICAMS is a high-performance machine designed for precision grinding tasks. With its advanced features, including a powerful motor and digital controls, it provides exceptional accuracy and surface finishes across a wide range of materials. This grinder is ideal for achieving tight tolerances and superior results in applications that demand both precision and reliability.

Brand: MTS

Model: 809

Type: Servo-hydraulic Axial/Torsional Load Frame

The MTS 809 servo-hydraulic Axial/Torsional load frame is capable of applying simultaneous axial and torsional loads and displacements to a wide array of specimens. This highly versatile test system is capable of everything from static testing to multiaxial fatigue characterization and offers superior stiffness for increased accuracy. The unit also has the capability of performing HIGH TEMPERATURE testing of materials.